On April 12 was held the official launch of Bzero, a hybrid electric system for zero emission navigation in the luxury yacht of Baglietto, that leverages renewables, photovoltaic power and hydrogen fuel cells, to bring sustainability within the sea travels.

Tempco proudly participated at the event as a technological partner of Baglietto. The constant and ongoing commitment of both Baglietto and Tempco to safeguard the environment have found a common point of contact in this highly innovative project.

The Bzero project, in order to create a more green and sustainable yachting, primarily aims at increasing the electric cruising range of vessels in zero-emission mode. In fact this is obtained thanks to the integration of hydrogen fuel cell technology on a hybrid or diesel-electric platform on board of the Baglietto yachts. Within the construction facility of Baglietto, a fully functioning prototype of the system has been realized, to be mounted on board on the manufacturer’s vessels.

Tempco contributed to the achievement of the objective by supplying the cooling systems for power electronics on board. Following an in depth study of the application, Tempco has been able to provide an efficient and compact solution that is, clearly and furthermore, completely customized upon the customer’s needs.

This very innovative and groundbreaking yacht requires indeed a refined and elegant design and engineering, both in terms of equipments and the luxury details of even the smallest finishing touch. Tempco has therefore achieved a relevant goal, proving that innovative engineering and luxury can go hand in hand while pursuing a common objective.

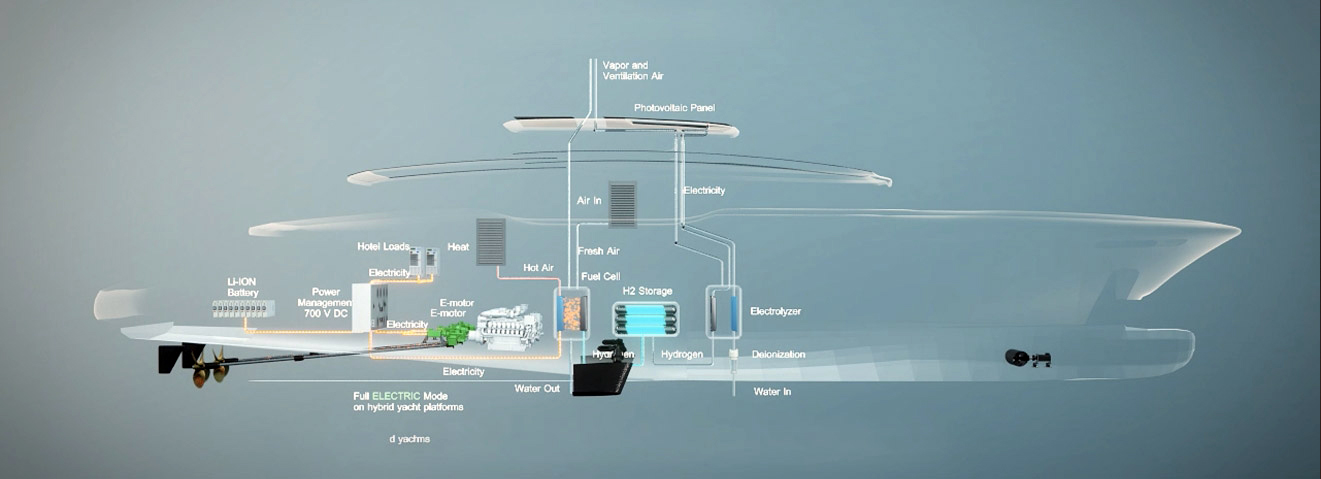

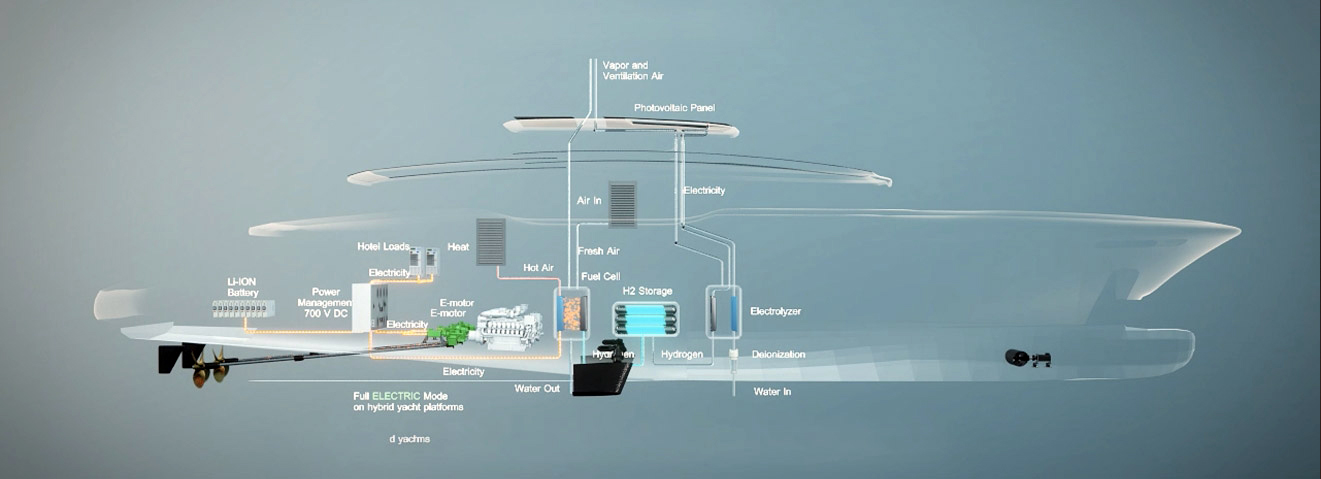

The technical scheme of the machinery clearly shows the highly innovative content of the Bzero project by Baglietto

The name Bzero (B raised to zero) means that the emissions produced during the travel of this yacht will be equal to zero. This is possible thanks to solar energy and to a hydrogen production module directly from seawater, filtered and deionized. This module produces the main fuel of the vessel, hydrogen, with 5.0 degree of purity at a maximum pressure of 35 bar through a system of AEM-type electrolysers (for a total power of about 55 kW). The electrolysers are primarily powered by energy from renewable sources (photovoltaic panels) and/or the electricity grid with the aim of producing as much ‘green hydrogen’ as possible.

In short:

➔ Seawater is collected, filtered and deionized by a hydrogen production module

➔ Starting from treated water, hydrogen is synthesized, providing the main green fuel of the yacht

➔ During the process, solar energy collected by photovoltaic panels is employed to power AEM-type electrolysers. These enable the correct functioning of each step.

➔ The final output, is clean and green hydrogen with zero emissions

Each one of these steps requires a fine control of temperature, and to achieve it Baglietto entrusted Tempco. Ad hoc engineered systems ensure the cooling of power electronic components on board, that include all of the electrical instruments serving the start and powering of the yacht. Once again, producing energy in an eco-friendly mode.

The video here below (courtesy by Baglietto), as a further proof of the efficacy and the care given to every detail of the project, suggests a hypothetical zero emission trip with the new Baglietto yacht. At eeach stop-over of the travel is it possible to see how the vessel recovers energy, so that its cruising is completely sea-friendly, safeguarding environment and the sea.

The final results shows the success of what once was just an ambitious project, and now in fact became a reached goal.

Tempco firmly believes that the future of mobility and sustainable transports relies on the correct employ of hydrogen and CO2. Using new sophisticated technologies, thanks to these sources, once considered just as production waste, it’s possible to completely change the point of view and look at the new opportunities that innovative technologies unfold for the mobility of the future.

Starting with quietly sailing in the blueness with Baglietto.

Stay updated on the latest applications of thermal energy management by subscribing our monthly Tempco Newsletter – Solid Temperature.