The new Regulation (EU) 2024/1834 is scheduled to come into force on July 24, 2026, defining new ecodesign requirements for fans with an electrical input power between 125 W and 500 kW. The new regulation replaces the old Regulation (EU) 327/2011 and aims to tighten the minimum energy efficiency levels these devices must meet.

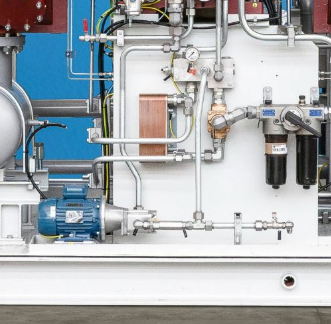

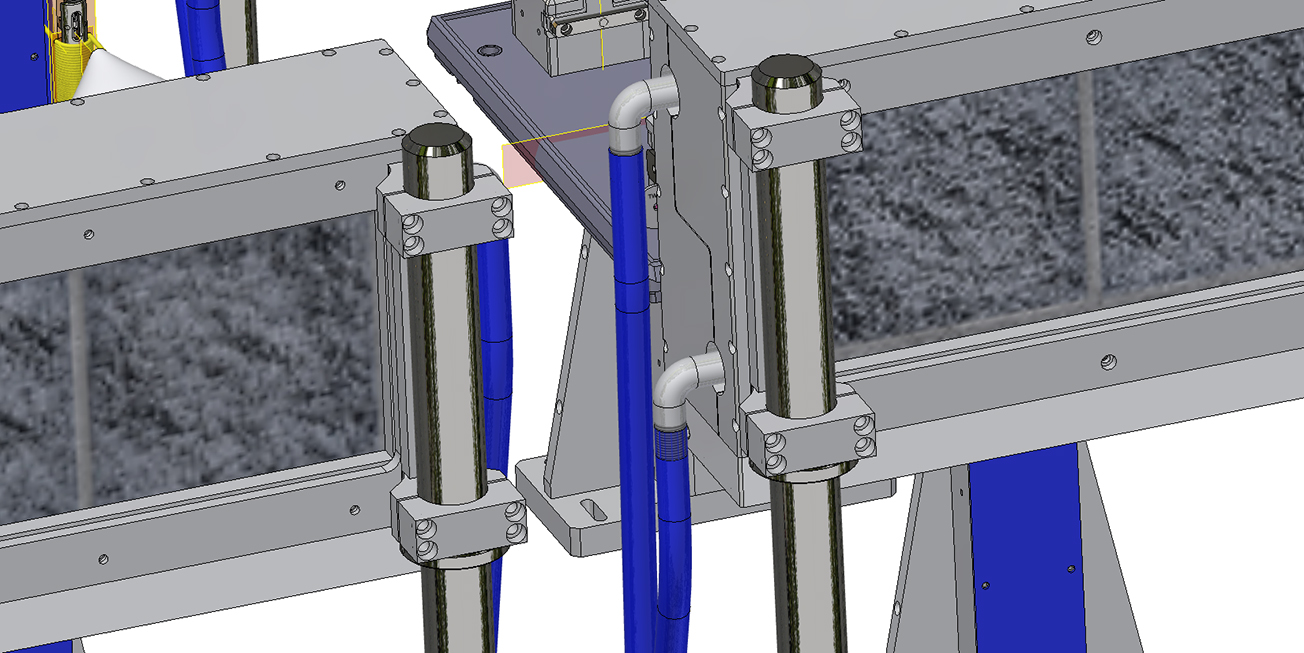

These devices are widely used in temperature control, cooling, and thermoregulation systems in the process industry developed by Tempco. The regulation defines a fan as a device consisting of at least three components: stator, rotor, and motor. The fan must therefore achieve the minimum required energy efficiency at its optimum operating point, where efficiency is calculated as the ratio of airflow performance to electrical power input.

The new Regulation on electric fans also requires more information on partial loads and specifies the documentation requirements for the manufacturer/distributor/user, including information on reparability in addition to efficiency. The regulation thus aims to promote the development of the circular economy through the availability of spare parts.

The new requirements, which increase energy efficiency performance levels for fans compared to those established by the previous Ecodesign Regulation, will therefore further reduce energy consumption in industrial systems for temperature control and cooling. These savings can also be further increased in electric fans through the use of inverters and systems that adapt air volume to actual process needs, thanks to speed regulation.

Fans that comply with the minimum energy efficiency limits set by the regulation are recognized by their CE labeling, certifying their compliance. Only fans that comply with the CE regulation will therefore be allowed to enter the European market, regardless of whether they are manufactured in the EU or imported from non-EU countries.

Finally, a transition period until July 24, 2027 is foreseen to comply with the new efficiency requirements and the extended documentation requirements imposed by the regulation for fans installed in other products, so-called built-in fans.