In Tempco we ride the wave of Summer, and we wish you’re gonna spend a relaxing and cool August!

Enjoy your Summer Holidays, and see you back here in September!

And as always… Stay efficient! 😉

In Tempco we ride the wave of Summer, and we wish you’re gonna spend a relaxing and cool August!

Enjoy your Summer Holidays, and see you back here in September!

And as always… Stay efficient! 😉

Which cooling system is the better choice to obtain cooling water for production processes, among chillers, evaporative towers or dry coolers, is a very often requested topic. The choice depends first of all on the temperature level of the water required. Clearly, if water at 10° C is needed, or even at 0° C or under zero, the only way to go is a refrigerating group, or chiller.

But there are several halfway situations too, where cooling water required has slightly higher temperature levels, such as 20-25 or 30° C. Which still is cold water, but it can be obtained leveraging other kind of cooling systems. Each one offering its benefits and disadvantages, clearly.

The refrigerating group is the one that is less affected by climatic conditions, if properly designed. There are also chillers tropicalized, able to operate also at high ambient temperatures, and with to special equipments enabling operations as well during the winter season. We’re talking here about EC fans, that provide the adaptation of the condensation speed.

When cooling water is required at temperatures of 25-30° C, that’s when the doubts start, if it’s better choosing a chiller, an evaporative tower or a dry cooler. It all depends on the climatic conditions. An evaporative tower employed at latitudes typical of North or Central Italy, and Europe, allows to obtain cold water at a temperature of approximately 29-30 or 31° C. Here, a dry cooler struggles, just because it’s cooling work depend strictly upon the ambient temperature. So that during the summer season, when temperatures reach 30-35° C, it will be possibile to obtain cooled water at temperatures 5° C higher, and so that means water at 35-40° C. Furthermore, it’s true that during the winter season, or the mid-season, a dry cooler allows to have cold water at the required temperature.

In the comparison between a cooling tower and a dry cooler, the first one has the advantage to have an open circuit of the water, while dry coolers employ a closed circuit, with impacts on the performances. On the other side, having a closed circuit of the water means that there are no side effects caused by dust present in the external air, nor evaporation or water consumption, avoiding the need of refilling treated water.

However, with water in a closed circuit there is the risk of freezing during the winter, that could cause breaks on pipes, and thus requiring the employ of glicol.

It’s overall a complex theme, and the right solution has to be carefully evaluated case by case. A trend ongoing lately is to combine chillers with dry coolers, that during the winter season can easily replace the operations of the chiller, allowing to switch-off the compressors. With significant gains in terms of energy savings. The same dry cooling systems can be achieved using an evaporative tower, but taking care of interposing a heat exchanger, because the open circuit of the tower exposes water to contamination, and therefore cooled water should be treated prior to feed the industrial production process.

Subscribe here to our Tempco Newsletter – Solid Temperature.

Hydrogen and fuel cells foster a great opportunity for the deployment of sustainable and clean mobility of future, alternative to electric vehicles. For a project related to a hydrogen truck, we are supplying in several steps a series of brazed plate exchangers, completely manufactured in stainless steel.

The heat exchangers are employed on the hydrogen vehicle to transfer the heat from the cooling circuit of the fuel cell to the main cooling circuit of the vehicle, in order to maintain the two cooling circuits separated.

These are in fact heat exchangers of the same version as common brazed plate heat exchangers, but instead of copper they are completely made in using stainless steel.

The project started one year ago and required a series of sizings and technical refinings, in order to define the model of heat exchangers to be supplied. As usual in these kind of brazed plate heat exchangers, and even more in this particular case, the exchangers have been pressure tested and also passed destructive testing, in order to ensure maximum reliability of the thermal transfer equipments.

Subscribe here to our Tempco Newsletter – Solid Temperature.

Previous videos focused on anodic oxidation applications triggered some questions, mostly referred to the selection of corrosion resistant materials in heat exchangers. In fact, heat exchangers employed in anodic oxidation have to work with solutions of sulphuric acid with 20% concentration, at temperatures of approx 20-25° C. Based on ISO-corrosion diagrams, these conditions would suggest the use of AISI 316. But the risk in these kind of plants is that the temperature goes even higher, for example during the shut down of the plants during the summer season.

Another kind of material must then be selected, being the Avesta 254 SMO, a high-performing alloy which offers excellent corrosion resistance even at high concentrations of suplhuric acid and temperature levels. In case it’s not enough, it is also possible to use Titanium, commonly employed with seawater applications thanks to its excellent resistance to high concentrations of chlorides and high temperatures.

Talking about costs, if AISI 316 represents 100, for both Avesta 254 SMO and Titanium the cost is about 200, depending on variations on the market.

When sulphuric acid concentration gets higher the problem gets more complicated, and Avesta and titanium are no more suitable. It is therefore necessary to use Hastelloy C276, another high-performing alloy with a quite high cost and with relatively low availability on the market. Anyway, this is a kind of material that can be cold-printed, and so a perfect solution for plates in heat exchangers.

The options are quite similar in case of shell and tube exchangers, being it possible to find on the market tubes in Avesta 254 SMO, and also titanium pipes even if it can be a little more difficult, as well as for Hastelloy C276. But there are also other materials that can be employed here, such as Incoloy and Monel. These are anyway more sophisticated materials, involving higher costs both for the raw material and the working process.

When the corrosion level goes even higher, it’s also possible to use graphite exchangers. These are exchangers with a peculiar construction, in some way similar to plate and shell and tube exchangers, made using mixtures of graphite.

Moreover there are plastic exchangers, in particular U tube bundle exchangers consisting in an ensemble of tiny plastic tubes to be immersed inside the tank to be thermoregulated. Usually these are made using polypropylene or PVC or other plastic materials, depending on the kind of application, workability and the temperature levels. Involving heating tasks, in fact, using plastic always requires great attention.

Finally, leaving the anodic oxidation field and entering the pharma sector, talking about resistance of materials using corrosive fluids there are also exchangers and reactors made with glass. Anyway, this is a completely different industrial production environment, with very different levels of accuracy and much more delicate than more ‘heavy’ anodic oxidation plants.

Subscribe here to our Tempco Newsletter – Solid Temperature.

The ‘magic word’ is non-clogging filling packs on cooling towers. A long-term customer of Tempco, with several textile facilities around Europe and an important installed park of evaporative towers, launched a few years ago an intervention to increase performances and efficiency on operational costs of these machinery.

Some year ago we did a complete analysis of critical issues involving plants using evaporative towers, installed in a couple of industrial production facilities. In collaboration with an engineering and design studio, we made it clear that the rapid and excessive clogging of the filling packs within the towers generated a decrease of their cooling capacity, combined with a gradual increase of power consumption.

The technical office then agreed on testing a tower equipped with a non-clogging filling pack, different from a splash type one, obtaining quite good results that convinced them to adopt this solution as a standard for all of the plants, first equipment cooling towers but also for the revamping of existing ones.

Now following an annual maintenance and integration program, the customer is gradually substituting all of the filling pack systems of its towers, even if it requires bigger machines, and therefore a higher first investment cost, but with a two-seasons long ROI, achieving a strong decrease on maintenance and energy consumption costs.

Subscribe here to our Tempco Newsletter – Solid Temperature.

Mono fluid thermoregulation systems are gaining more and more ground within the pharmaceutical sector, for the precise temperature regulation of reactors. These solutions allow to achieve the chemical reactions required for the production of active principal ingredients, for example, carefully following production recipes that require a defined thermal program.

Mono fluid thermoregulation units are therefore systems that, if properly programmed, allow to follow the thermal scheme of a reactor or a chemical equipment. The units allow to monitor, control and regulate temperatures of the product inside the reactor. Mono fluid thermoregulation employs a circulating pump, ensuring the flow of the fluid between the jacket of the reactor, or the half pipe of the equipment, and an array of heat exchangers, or electrical heaters. The whole system is managed by an electronic regulator that controls the temperature of the fluid.

On the secondary circuit it is possible to have vapour, employed to heat the fluid, and refrigerated water or cooling tower water for the cooling of it. If vapour is not available, a heating section can be employed using electrical resistors, managed as well by the electronic regulator.

The system can be managed by remote using a PLC, an electronic regulator or other interfaces. It is then possible to control a quite varied range of temperatures, starting from under zero temperatures down to -30°, going up to very high temperatures, reaching also 250° C. Depending on the range of temperature required, the fluid employed will be simple water, or glicol water with anti-freeze to reach low temperatures. Pressurized water, over-heated, is employed to reach temperatures up to 140° C, and finally diathermic oils or silicone oils are employed for high temperatures.

Diathermic oil is usually employed for plants involving only high temperatures, while silicone oil, or synthetic oil, is used in plants requiring a wide range of temperature regulation, from under zero up to very high temperatures. These oils have indeed the characteristic of having a good flowing property at low temperatures, and also offer good thermodynamic and physic properties at very high temperatures.

These units can be provided compliant to several regulations, depending on the kind of application or the Country of installation. Taking about chemical and pharmaceutical industry, it will very common to be in presence of an explosion risk environment, thus requiring an Atex execution. If the units are for installation within the United States these will be compliant with UL regulations, while if the destination is Russia they will be provided with EAC certification.

Very often mono fluid thermoregulating units have to be combined with dedicated refrigerating groups, not directly integrated within the unit in order to ensure production continuity in case for example of a fault in the cooling section. This kind of thermoregulation systems must indeed be conceived to ensure maximum flexibility, maximum reliability and extreme precision in temperature control.

Subscribe here to our Tempco Newsletter – Solid Temperature.

We collaborate since approximately 10 years with a customer that operates in the lead-acid batteries recycling, providing special cooling systems employed on the burners within the plants, aimed to the recovery of materials.

These systems present a quite typical composition, which includes:

A peculiar characteristic of the solution is the redundancy of equipments, due to the fact that for this kind of application, requiring extreme operating conditions and working constantly 24/7 during 365 days per year, it’s absolutely necessary to always ensure the availability of the cooling process.

The presence of lead-acids also eventually creates a very harsh and aggressive working environment, and therefore another characteristic is the employ of stainless steel materials for the construction of the instruments.

Subscribe here to our Tempco Newsletter – Solid Temperature.

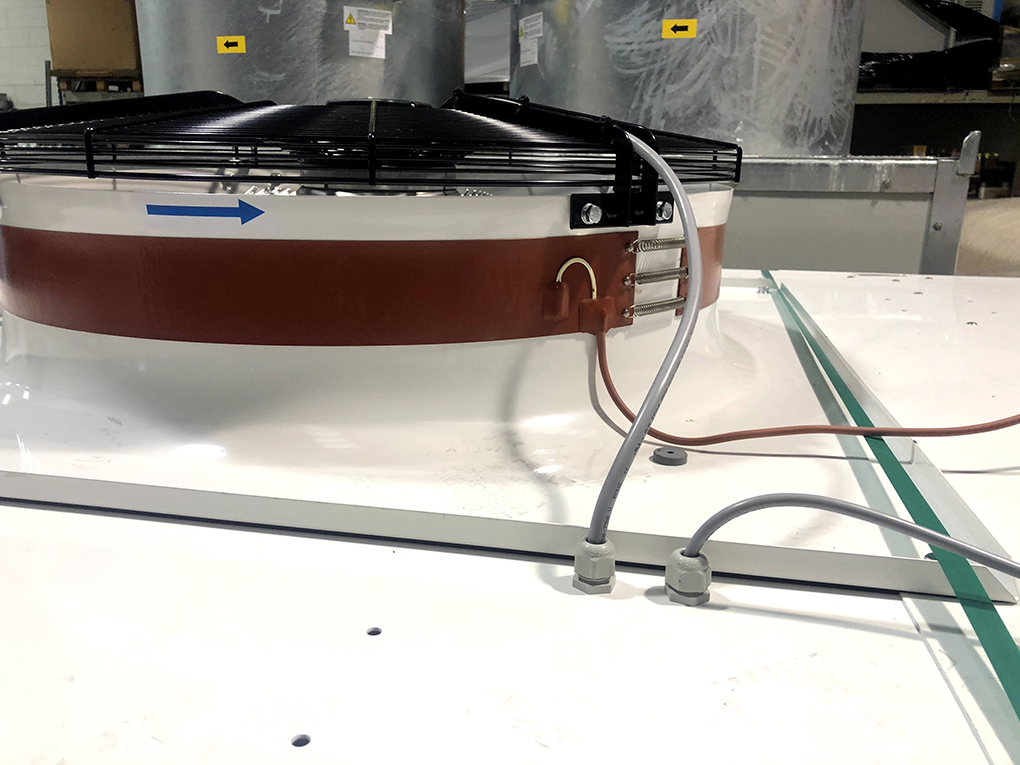

An actual trend in energy saving is the implementation of free cooling systems combined with chillers to achieve cooling in industrial processes.

When a production process requires for example cold water at the temperature of 15° C, its is necessary to install a chiller that allows to obtain water at these temperatures for the whole time period of the year. But during the Winter season it’s possible to employ direct thermal transfer systems leveraging the low temperatures of external ambient air. These are dry cooling or free cooling systems consisting in thermal transfer arrays or huge radiators with ventilation that allow to cool water.

The convenience of installing these kind of systems depends on two main factors, first of all the latitude of the installation site of the plant. Secondary, the temperature levels required by the kind of industrial process involved.

Having for example a production process that needs cooling water at the temperature of 15° C, it will be necessary to have a chiller during the Summer season. But during Winter, or whenever the ambient air temperature falls down 10° C, it is possible to obtain water at the temperature of 15° C using a classic dry cooler. Achieving a significant energy saving: it is indeed possible to completely shut down the compressors of the chiller, while keeping only the energy consumption related to the pumps that provide the circulation of refrigerated water and the fans for ventilation. For a 100 kW plant, for examples, it leads to a saving of 30 kW of energy consumption related to the compressors per hour. The energy saving that can be achieved is then directly related to the thermal duty required.

It is therefore necessary to properly evaluate both the temperatures required by the industrial process and the average local seasonal temperatures, in order to estimate the return of investment in every specific case of the implementation of a free cooling system.

Subscribe here to our Tempco Newsletter – Solid Temperature.

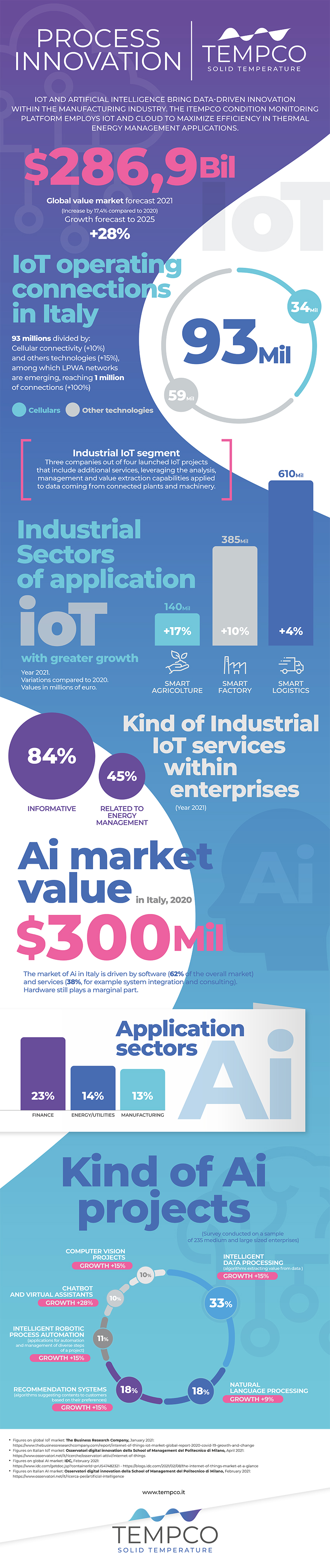

Here’s a new Tempco Infographic dedicated to the growing adoption of IoT and Artificial Intelligence solutions within companies in the manufacturing sector, pushing innovation of the process industry toward data-driven models. Connected machines and components ‘talk’ to operators and plant managers, allowing the real time monitoring of the state of production and at the same time of the conditions of manufacturing assets.

Real-time condition monitoring of processes and production systems allows not only to maximize productivity reducing waste and errors, increasing quality using optimization models developed with AI algorithms for specific industrial applications. The data science also allows to extend the life cycle of machinery and equipments, enabling new predictive maintenance functions to increase plants’ availability and reliability, avoiding expensive production downtimes.

IoT and AI combined provide at last a transparent insight on effective energy consumes of production processes, aiming to a constant real-time improvement of energy efficiency and costs reduction within the process industry. This is also the goal of the iTempco platform, which employs IoT, analytics and cloud to maximize thermal energy efficiency and energy saving in temperature control and thermal energy management applications for production processes of all kind of industrial sectors.

Subscribe here to our Tempco Newsletter – Solid Temperature.

For a chemical and pharmaceutical group, we have deployed two thermoregulating units for reactors employed in the production of APIs. The two systems are combined with a chiller that provides anti-freezing solution at a temperature of -10° C, serving the cooling sections of both units.

The thermoregulating units are completely framed and have been developed to implement monofluid thermoregulation of the temperature of the reactors.

Monofluid thermoregulation is indeed a solution very widely employed within the chemical and pharma industry. Here, a unique working thermal fluid flows within an array of heat exchangers, providing the diverse temperature regulation levels for each of the production steps. The solution avoids the downtimes related to empty and load operations of different thermal fluids inside the circuit, achieving in addition very fine levels of temperature control.

The two thermoregulating units have been equipped with state of the art technological solutions, in order to obtain very high levels of precision in the control of process temperatures with tolerances of +/-1° C.

Subscribe here to our Tempco Newsletter – Solid Temperature.