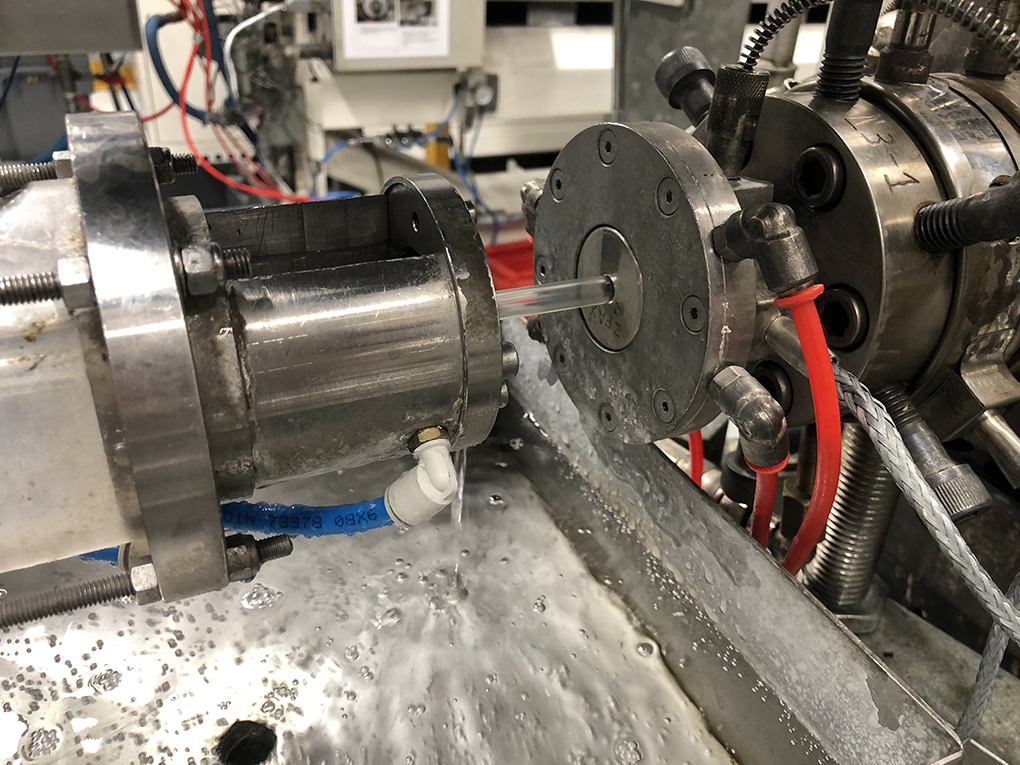

Previous videos focused on anodic oxidation applications triggered some questions, mostly referred to the selection of corrosion resistant materials in heat exchangers. In fact, heat exchangers employed in anodic oxidation have to work with solutions of sulphuric acid with 20% concentration, at temperatures of approx 20-25° C. Based on ISO-corrosion diagrams, these conditions would suggest the use of AISI 316. But the risk in these kind of plants is that the temperature goes even higher, for example during the shut down of the plants during the summer season.

Another kind of material must then be selected, being the Avesta 254 SMO, a high-performing alloy which offers excellent corrosion resistance even at high concentrations of suplhuric acid and temperature levels. In case it’s not enough, it is also possible to use Titanium, commonly employed with seawater applications thanks to its excellent resistance to high concentrations of chlorides and high temperatures.

Talking about costs, if AISI 316 represents 100, for both Avesta 254 SMO and Titanium the cost is about 200, depending on variations on the market.

When sulphuric acid concentration gets higher the problem gets more complicated, and Avesta and titanium are no more suitable. It is therefore necessary to use Hastelloy C276, another high-performing alloy with a quite high cost and with relatively low availability on the market. Anyway, this is a kind of material that can be cold-printed, and so a perfect solution for plates in heat exchangers.

The options are quite similar in case of shell and tube exchangers, being it possible to find on the market tubes in Avesta 254 SMO, and also titanium pipes even if it can be a little more difficult, as well as for Hastelloy C276. But there are also other materials that can be employed here, such as Incoloy and Monel. These are anyway more sophisticated materials, involving higher costs both for the raw material and the working process.

When the corrosion level goes even higher, it’s also possible to use graphite exchangers. These are exchangers with a peculiar construction, in some way similar to plate and shell and tube exchangers, made using mixtures of graphite.

Moreover there are plastic exchangers, in particular U tube bundle exchangers consisting in an ensemble of tiny plastic tubes to be immersed inside the tank to be thermoregulated. Usually these are made using polypropylene or PVC or other plastic materials, depending on the kind of application, workability and the temperature levels. Involving heating tasks, in fact, using plastic always requires great attention.

Finally, leaving the anodic oxidation field and entering the pharma sector, talking about resistance of materials using corrosive fluids there are also exchangers and reactors made with glass. Anyway, this is a completely different industrial production environment, with very different levels of accuracy and much more delicate than more ‘heavy’ anodic oxidation plants.

Subscribe here to our Tempco Newsletter – Solid Temperature.