During the summer break, last August, we completely renewed all of the heat exchangers installed within the production plant of a multinational manufacturer of plastic material grains.

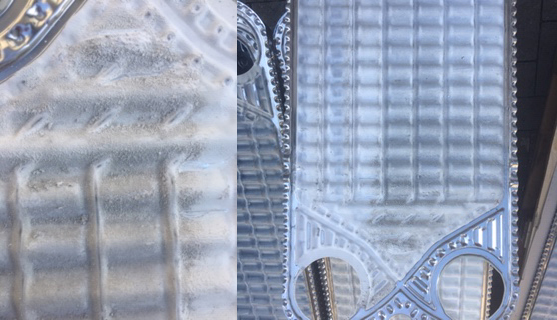

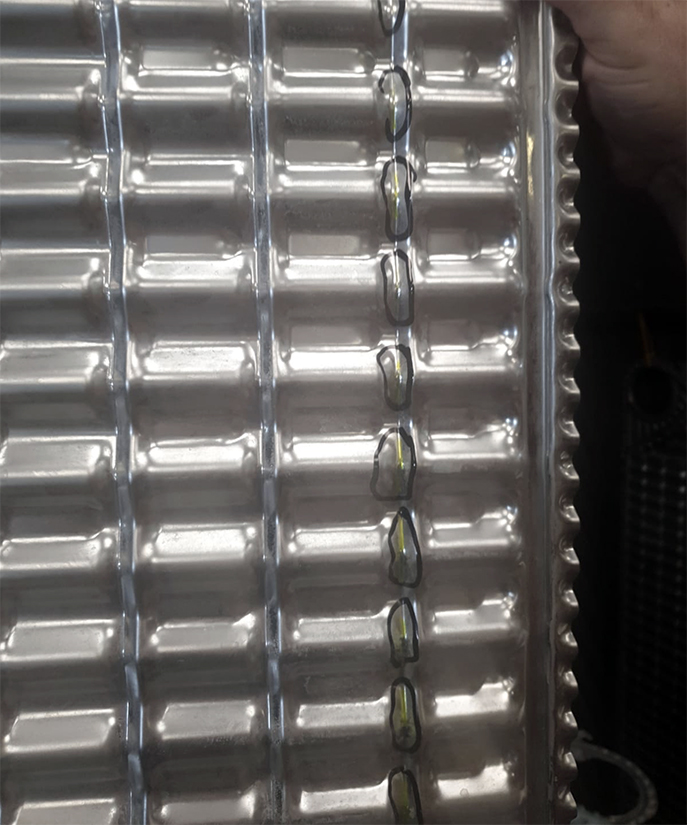

The exchangers were really in bad conditions, and the regeneration intervention has been complete and massive, involving the cleaning and re-gasketing of more than 200 free flow plates and 200 traditional plates, having a thermal transfer surface from 0,4 to 0,3 square meters each.

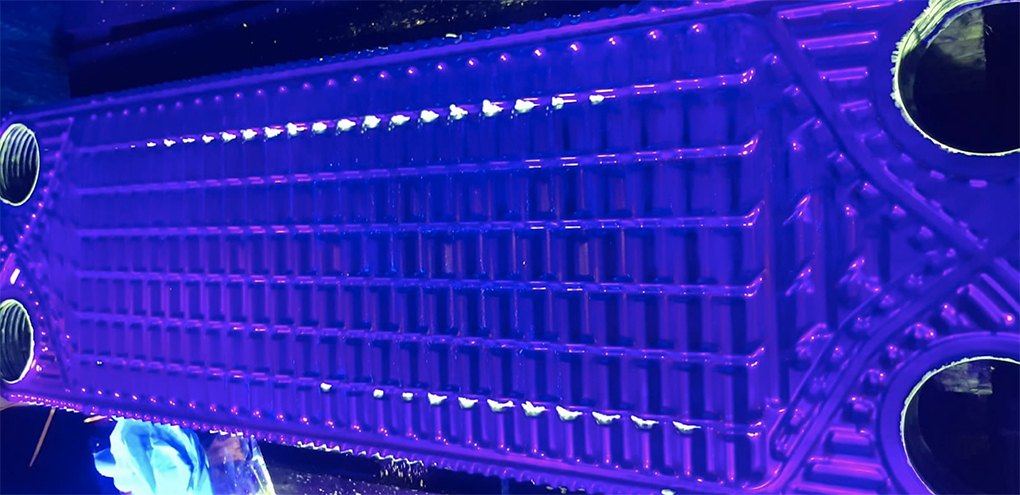

After the cleaning of the plates, with the removal of limescale, we proceeded with the test with penetrating liquids, represented here in these pictures with plates under a blu-purple light. This is a crucial step in order to identify all the cracks along the plates (appearing in brighter light).

The regeneration then also involved the frames of the exchangers, with the renewal of nozzles and related coatings.

The intervention had to be done in a very narrow time span. The customer, indeed, after a slowdown of the production during the lockdown period, had to be ready for the restart. We succeeded in respecting his requests, and all the maintenance and regeneration work has been made during two weeks in August. Everything was then ready for the restart of the production, which has been hectic.

Subscribe here to our Tempco Newsletter – Solid Temperature.