Let’s speak again about PCHE heat exchangers (printed circuit heat exchangers), that we have already treated in the previous videos in our Tempco Youtube channel and other articles. A few time ago we have participated at the event mcT Hydrogen, and it has been a very interesting event that showcased and anticipated the development of technologies in the hydrogen market for it’s distribution and compression and overall everything that refers to the hydrogen technology.

During mcTER we had many interesting leads, and in particular regarding the application of PCHE exchangers, which as I have often explained is definitely important. A peculiar application is related to the cooling of the gas in multistream exchangers.

For the compression and distribution of hydrogen, multi-phase compressors are employed in order to increase hydrogen pressure level. Hydrogen, between each phase, must then be cooled because otherwise it reaches levels that exceed the tolerances of the mechanical components of the compressors, thus meaning pistons, cylinders and the compressor itself.

Therefore so called inter-stage exchangers are employed, heat exchangers aimed at cooling the gas between the different phases. Clearly, hydrogen during the compression phase reaches high temperatures but also very high pressure levels, way much higher than other industrial gases usually employed. And so it is necessary to employ appropriate heat exchangers, and properly sized for this kind of application.

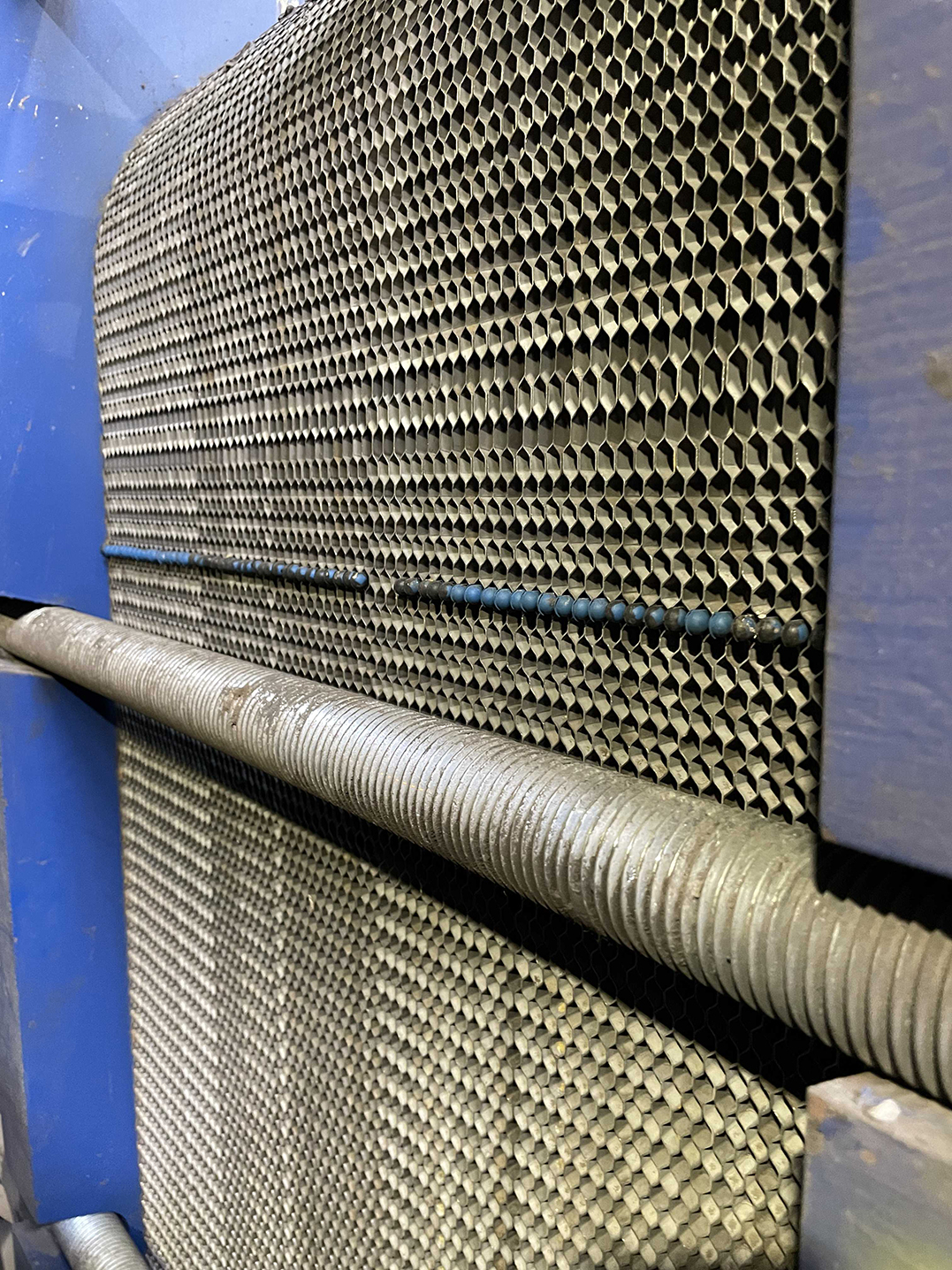

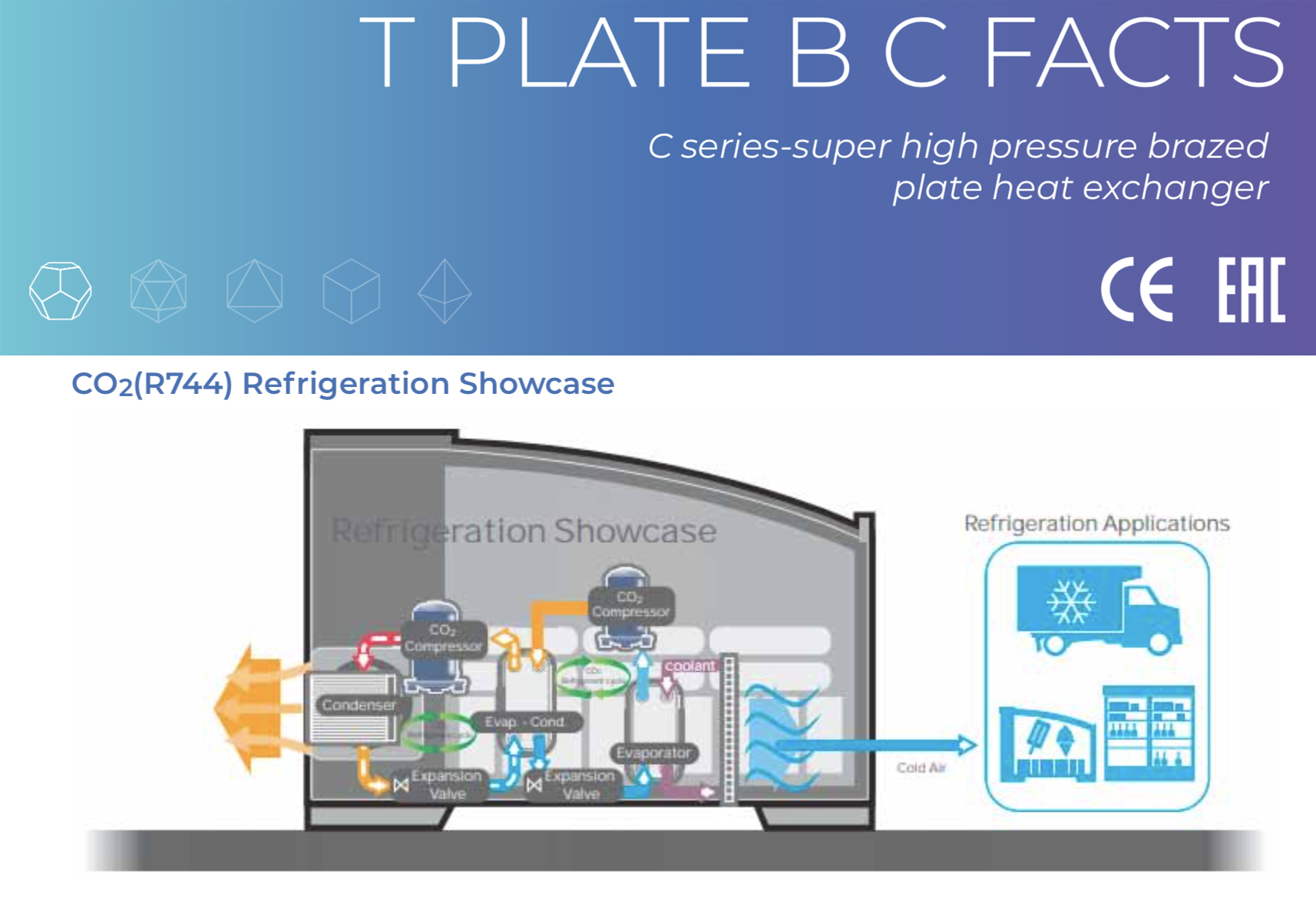

Shell and tube exchangers are normally employed, because they are able to withstand high pressure levels. Plate heat exchangers, even brazed ones, don’t indeed reach those pressure levels required because, for example, brazed plate exchangers for CO2 applications can reach a maximum working pressure of 140 bar. For sure a quite high pressure level, but not enough for the levels required in hydrogen compressors.

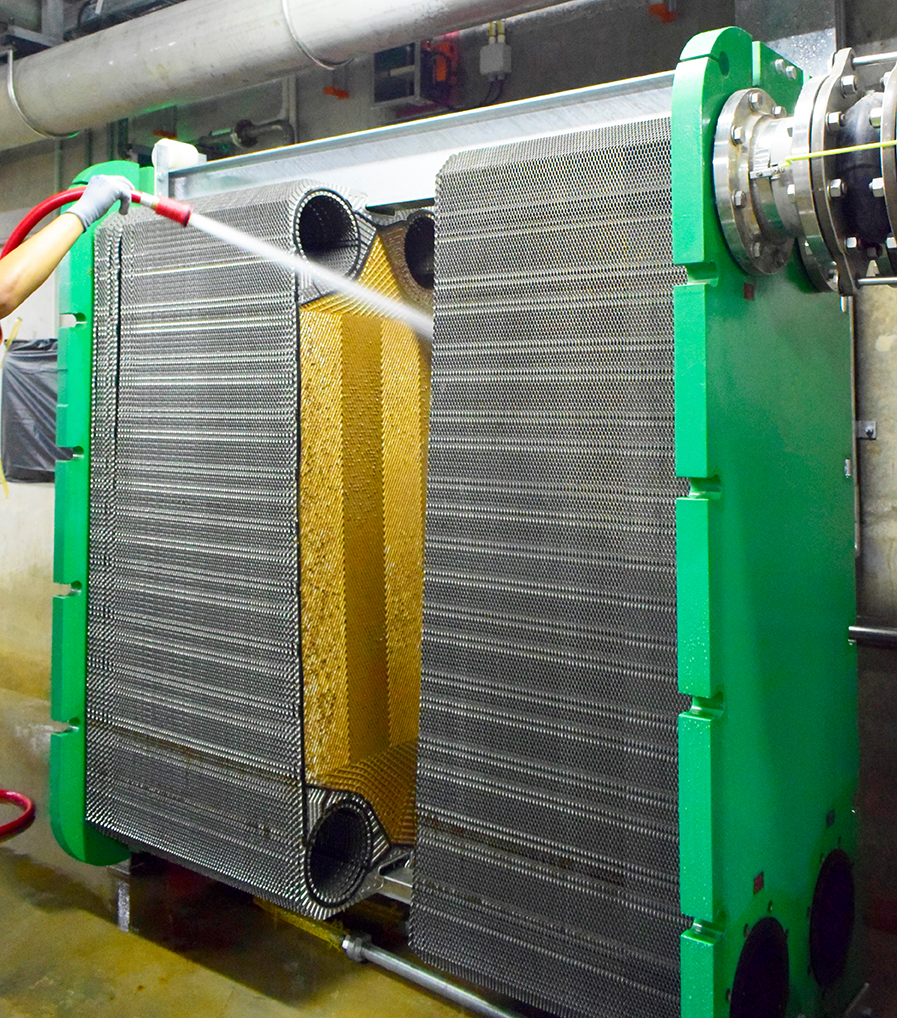

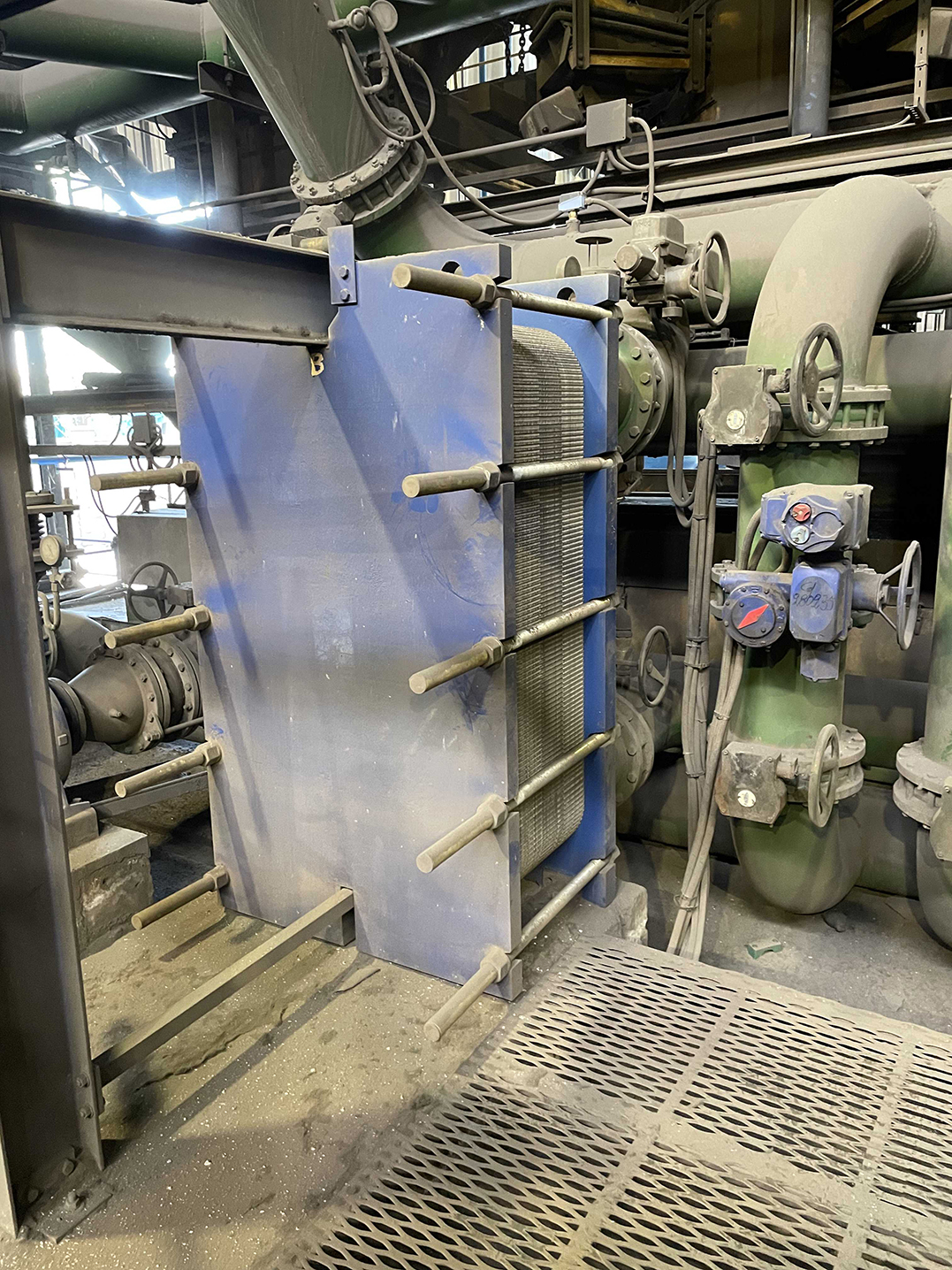

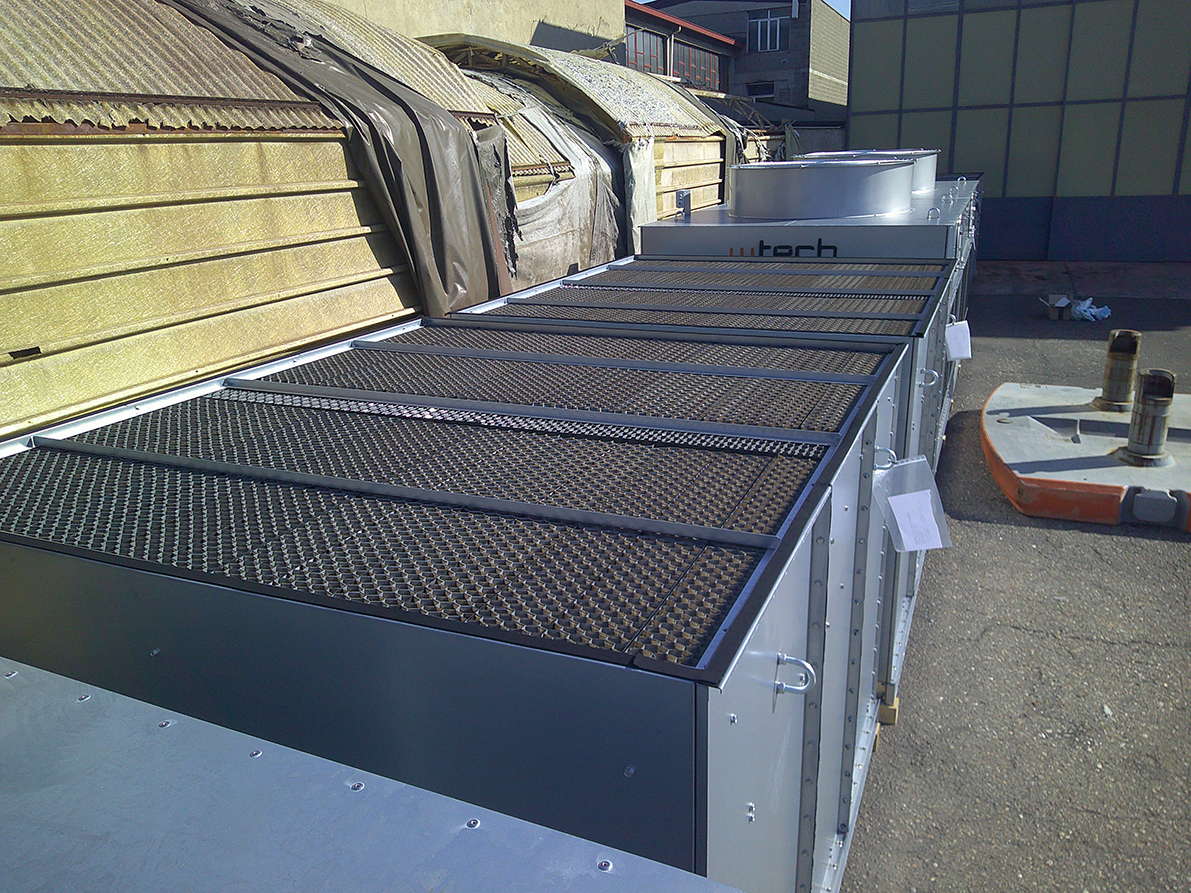

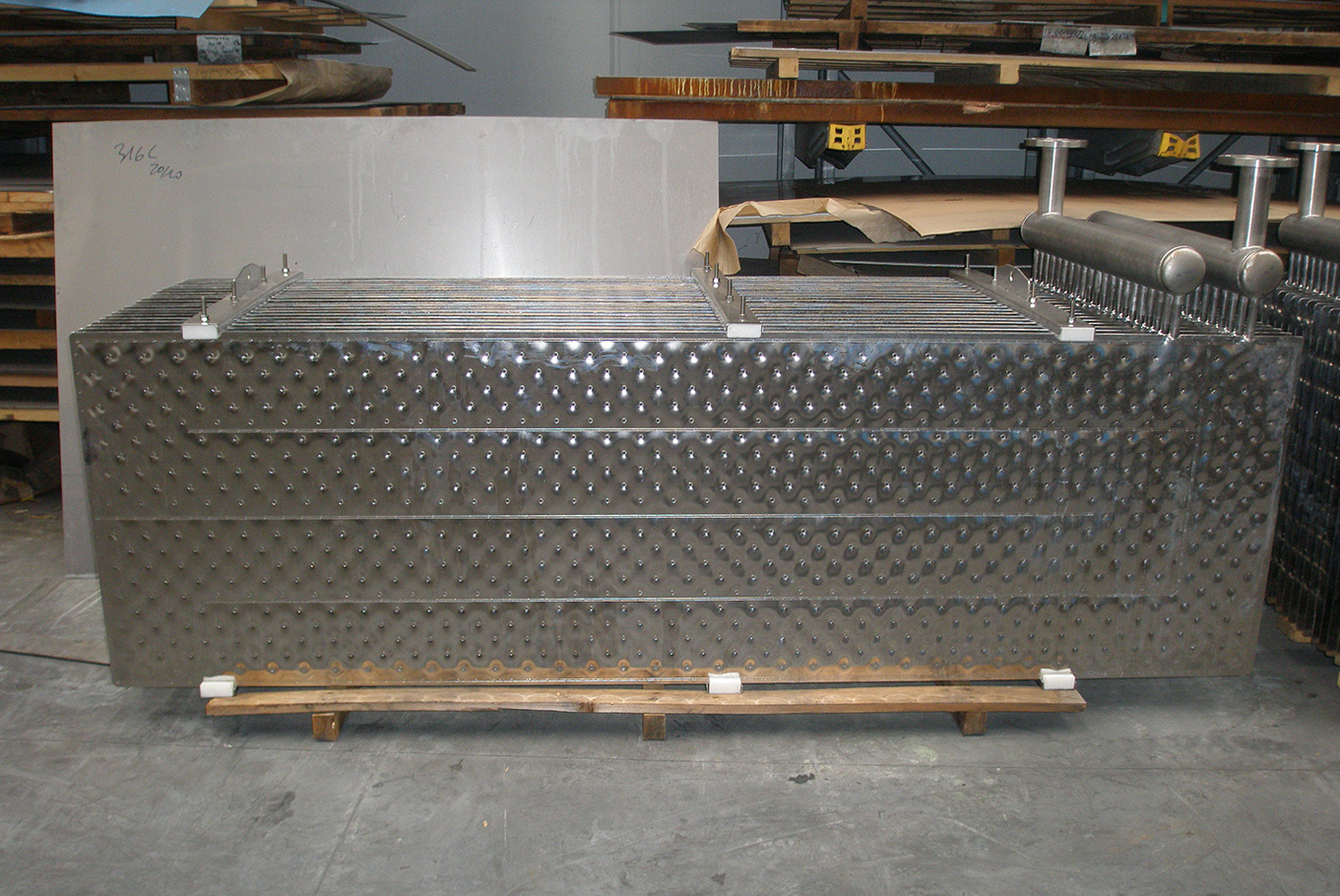

The solution is to employ PCHE exchangers, which are very compact and ensure the proper mechanical characteristics for this kind of application. In addition, PCHE exchangers can be also realized in multi-stream execution. So we can realize the exchangers as multi-stream, and therefore inter-stage in a unique exchanger, having a unique exchanger that works as a multi-phase exchanger for all of the compression phases.

The application is very interesting, very particular, and in Tempco we have already deployed it.