More on cogeneration in our new tutorial video on the Tempco Youtube channel (turn on subtitles for english). We’re focusing in particular on biogas, one of the most employed fluids in cogeneration plants. Produced from organic waste, the biogas represent an excellent fuel for engines employed for heat and electricity combined generation.

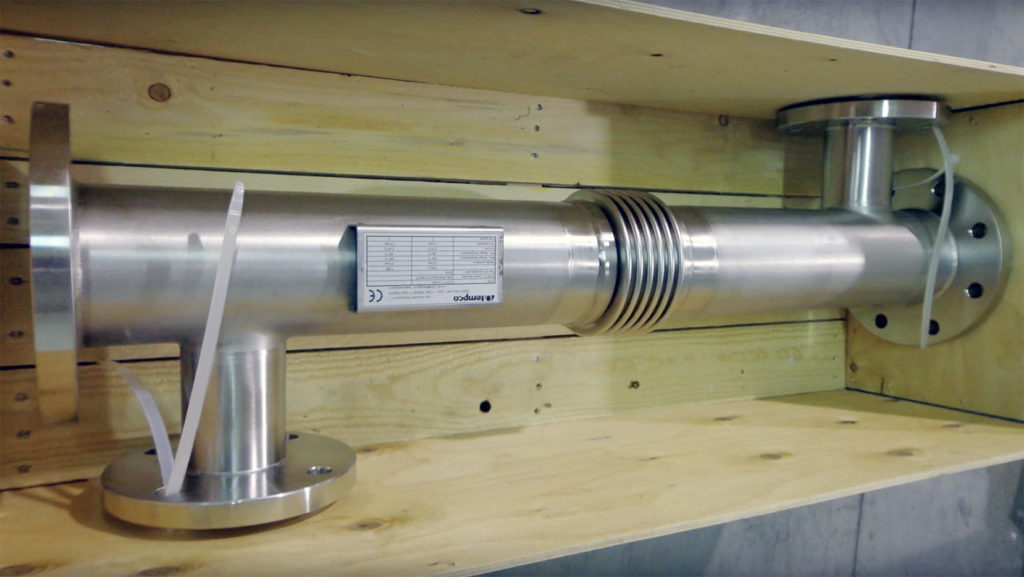

We have here a very virtuous production chain, an example of what is called circular economy, recovering wastes to obtain power generation. Shell and tube heat exchangers are the suitable choice for biogas cogeneration applications. Previous to the proper combustion cycle, the biogas must be treated in order to eliminate all the polluting elements that it gathers and also to extract all the humidity contained, which in case of combustion can damage the engines irremediably.

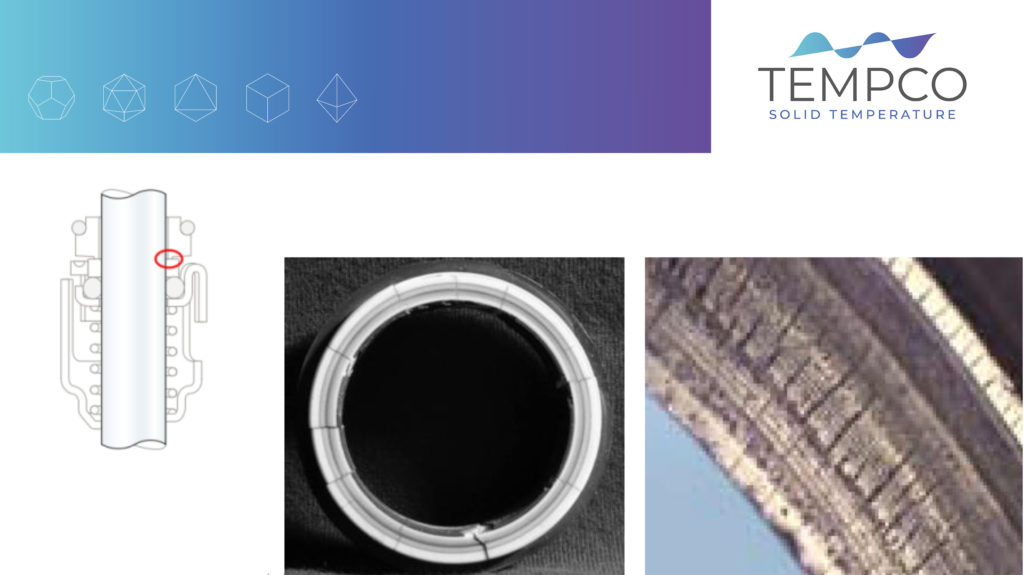

Biogas treatment include a part of thermal treatment for the dehumidification of these gases, which are usually at the temperature of approx. 34-40° C. The biogas is cooled down using a chiller working at very low temperatures, about 0° C, combined with a shell and tube exchanger with the cold fluid (water and antifreeze) flowing inside the shell. The biogas flows inside the tubes. The tubes are usually straight and sliding to facilitate cleaning operations from deposits that the gas can gather, but also to drain all the water condensed in contact with the cold flow of the glycol water. The condense must drain perfectly and get collected in a condense separator on the outlet of the exchanger.

The application usually requires long exchangers, in order to allow the biogas to flow inside the tubes as long as needed to ensure the complete elimination of all the humidity. Dedicated blowers send then the dehumidified biogas to the engine, and sometimes it can also be post-heated to obtain a proper combustion temperature.

Construction materials are usually carbon steel for the shell, without expansion joints due to the short temperature gap involved. Headers can be as well made of carbon steel, while the tubes can be made of copper. In case the biogas presents high levels of aggressive and corrosive elements, both headers and tubes must have a full stainless steel construction.

The tubes are pressed and, my personal choice, welded, in order to avoid any risk of leaks of glycol water from the shell inside the biogas flowing in the tube section.