Mechanical seals employed in machinery with rotating components can be affected by a series of wear issues. The main cause of mechanical seal problems is related to the correct lubrication of the seal itself. These are the main signs and causes of a scarce or wrong lubrication in mechanical seals aiming to a proper troubleshooting.

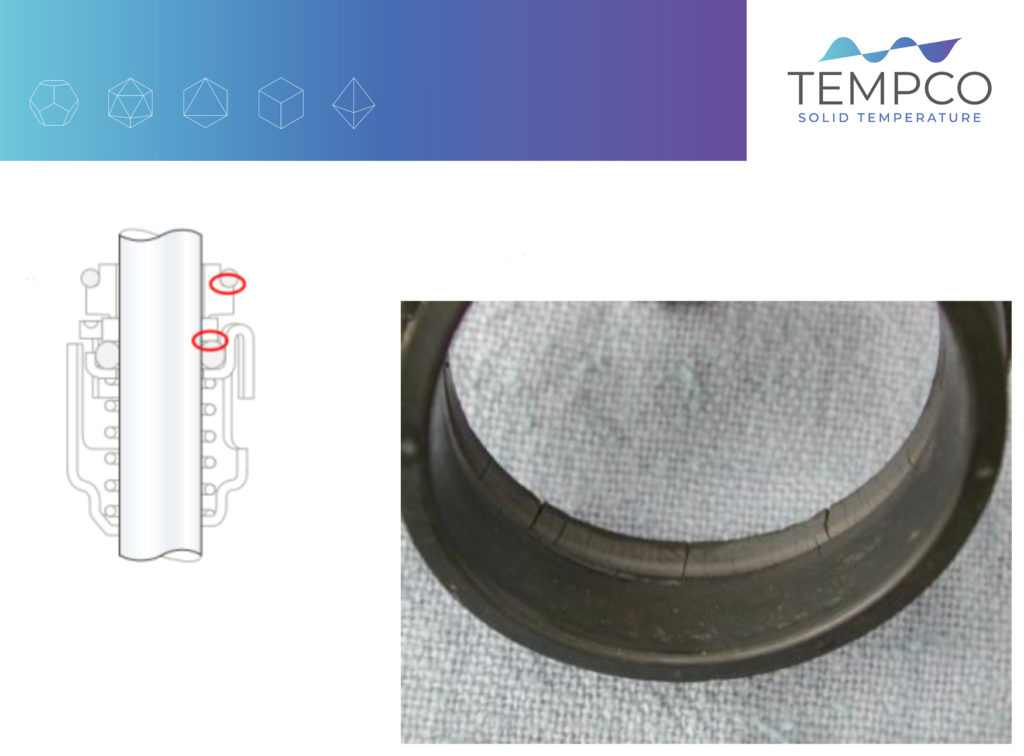

Dry running

Dry running happens when there is no liquid at all around the mechanical seal. The absence of the liquid film generates friction between the faces of the seal, with a dramatical increasing of the temperature. The typical damage of dry running is the presence of burned elastomeric parts. The damage happens when the O-ring is in direct contact with the over-heated mechanical seal ring.

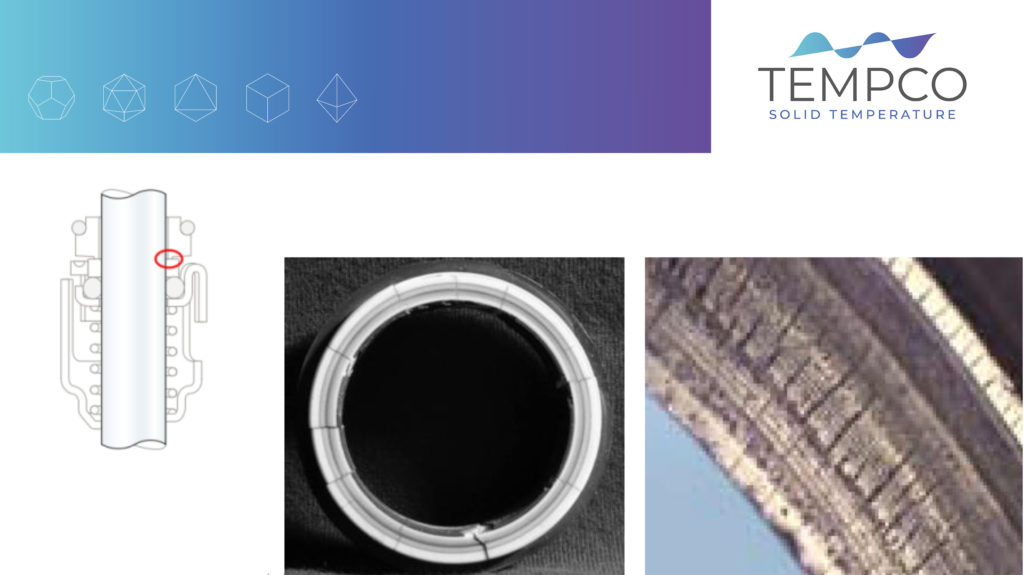

Insufficient lubrication

A scarce lubrication can happen when the pumped fluid has a very low viscosity, or when temperature at atmospheric pressure is higher than boiling point, or if there is some air in the circuit. In these cases, the heat caused by the friction can concentrate on small areas on the seal surface, with the result of even extreme heating conditions. Local alternation of heating and cooling of the mechanical seal surfaces can cause small radial cracks due to the thermal shock.

Absent or scarce flow

It happens when the pump circuit is working with the inlet valve closed. Heat generated by the friction on the shaft seal can generate very high temperatures. The temperature increase can thus damage elastomeric parts of the mechanical seal. In addition, it increases the risk of dry running on the surface of the mechanical seal.

Further mechanical seals problems can also be related to installation issues, failure in components or a wrong selection in materials matching. We will dedicate another article to analyze in depth the troubleshooting of these cases.