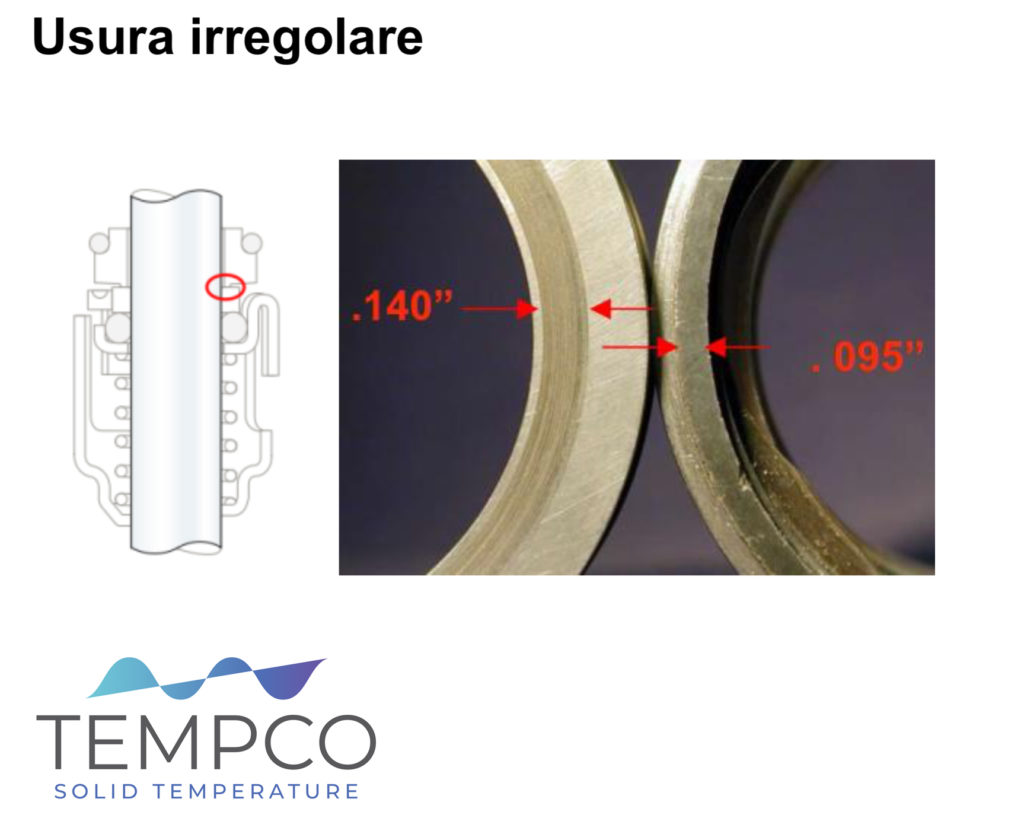

Chapter two on the topic of how to detect and recognize the causes of mechanical seal troubles, after the post dedicated to the problems related to lubrication. Mechanical seals can undergo a series of different kind of wear. An irregular wear can be the consequence of an excessive wear on bearings and in presence of vibrations.

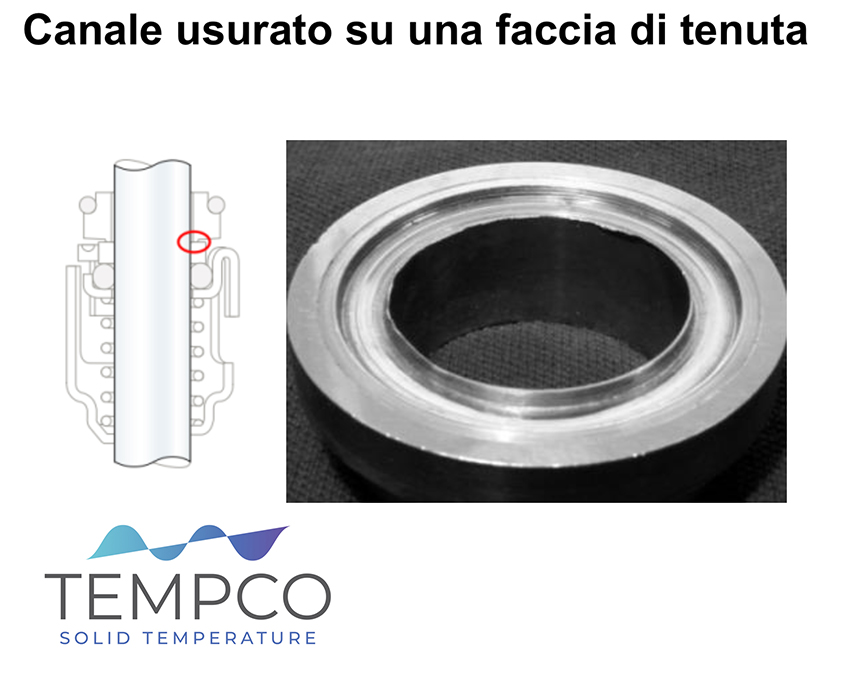

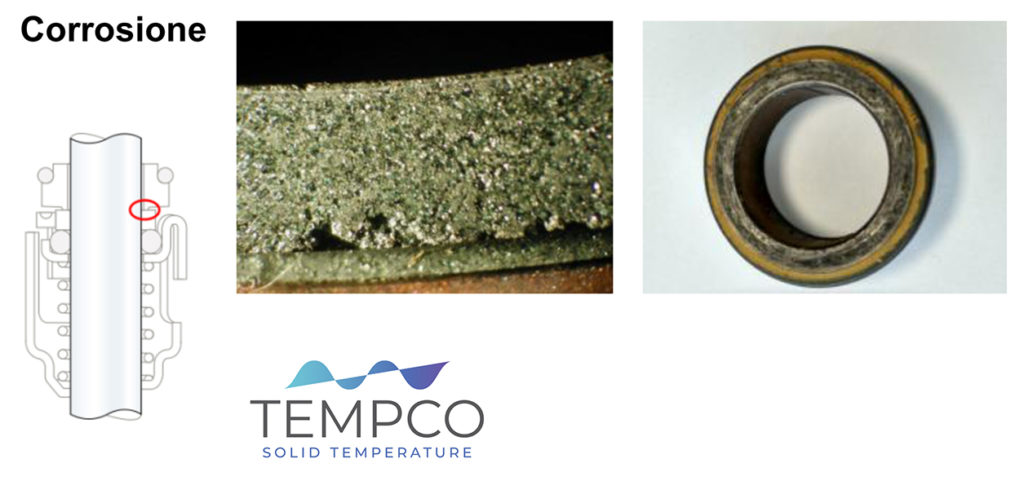

Small amounts of tough particles in the fluids can also lead to corrosion on mechanical seals: by sedimenting on the seal’s surface, these particles act like cutting tools in a grinding machine, damaging contact surfaces. An intermittent spotted wear on the seal surface can also relate to an imperfect linearity of the seal surface itself, due to defective mechanical construction of the seal, or even due to a wrong mounting.

Mismatched materials and fluids

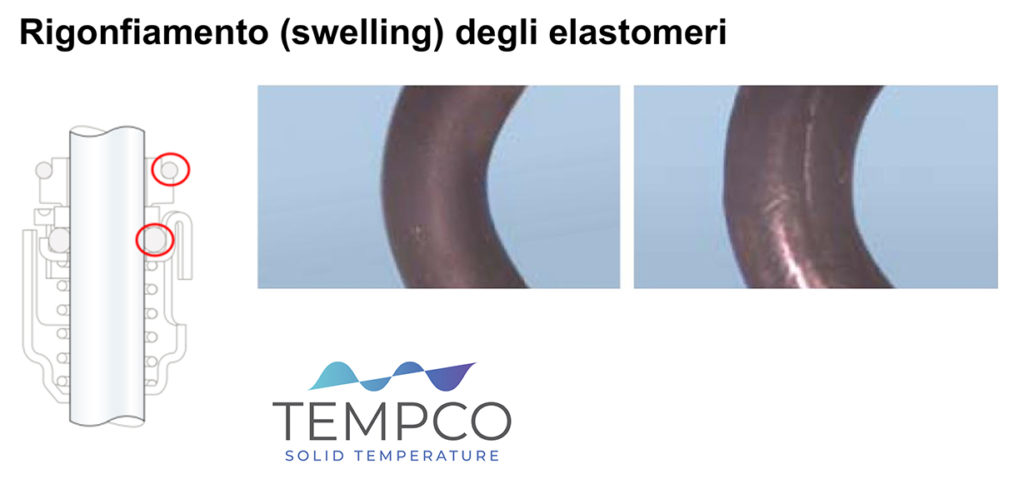

The right choice of seal’s materials is essential to ensure a long mechanical seal working lifetime, enabled by the compatibility between the seal’s material and the pumped fluids. A wrong matching can lead to swelling problems in elastomers, boosted by the high temperatures and the long exposure periods involved. Corrosion on mechanical seals can also be provoked by the incompatibility between materials and fluids, deteriorating the seal surfaces.

Installation and connections

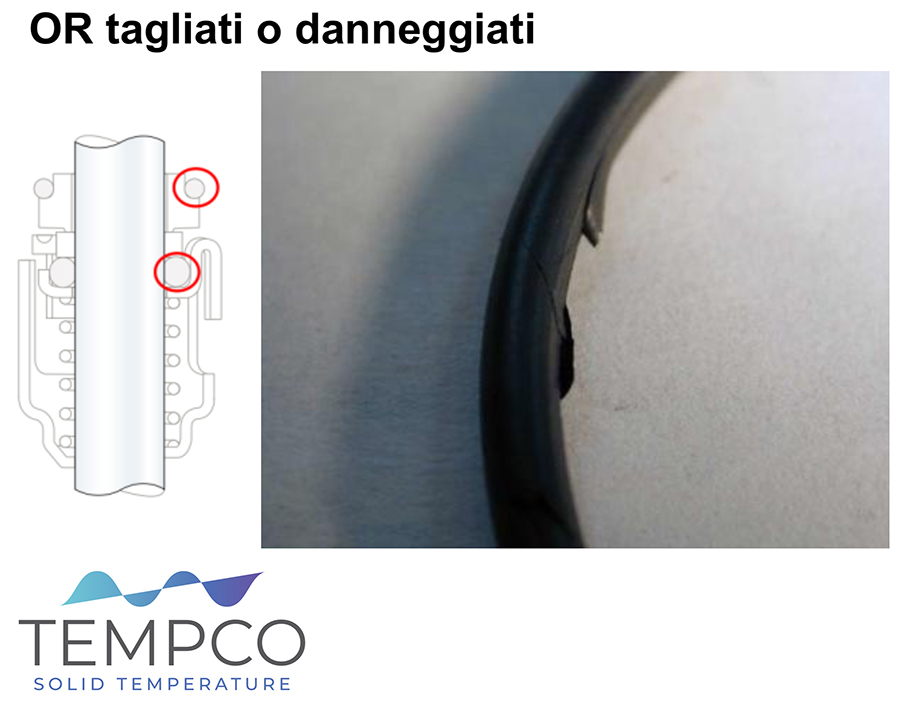

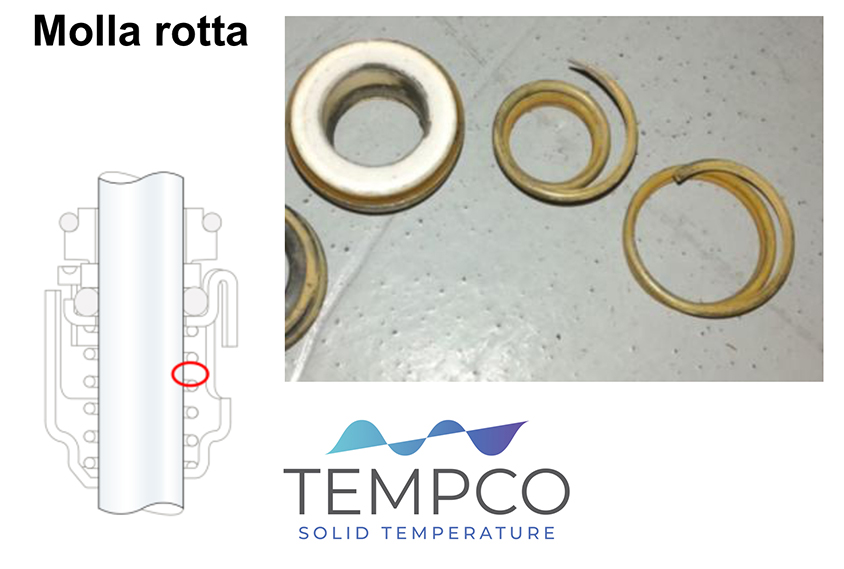

The correct installation is also a key factor to preserve the conditions of a mechanical seal. Pictured here are two examples of damages related to a wrong installation of the seal, leading to cut or damaged OR and breakage of the seal ring.

Also the working pressure of the pump must be comprised in the range of design values of the mechanical seal. In case of excessive pressure, the seal can be damaged irreversibly. At last, pay attention to the rotation verse of the pump, to avoid a breakage of the spring. This breakages can happen with a wrong electrical connection of the engine, a pump installed in parallel without a check valve, or also with a return flow when the pump is off.

The Tempco Service is at your disposal to solve any doubt or needs.