The attraction and elective affinities between heat exchangers and additive manufacturing are very strong and getting more and more triggering, as it’s clear to see while reading this interesting article published by All3dp focused on the many advantages that 3D printing brings into the world of heat exchangers. While designing and developing more efficient heat exchangers for cooling and heating tasks in industrial processes, there are indeed two main targets: increasing the thermal transfer surface and reducing at the same time the pressure drops.

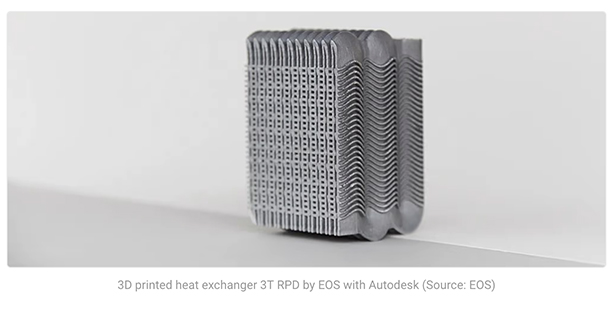

The total design freedom offered by additive technologies allows the complete re-imagining the design of heat exchangers.

The source article mentions the example of a recently developed prototype of heat exchanger realized by GE Research called UPHEAT – Ultra performance heat exchanger enabled by Additive technology: this heat exchanger can handle temperatures up to 900° C, which means 200° C above the maximum level that actual heat exchangers can stand. GE Research says the exchanger could find applications in the energy sector, enabling a more efficient and cleaner power generation.

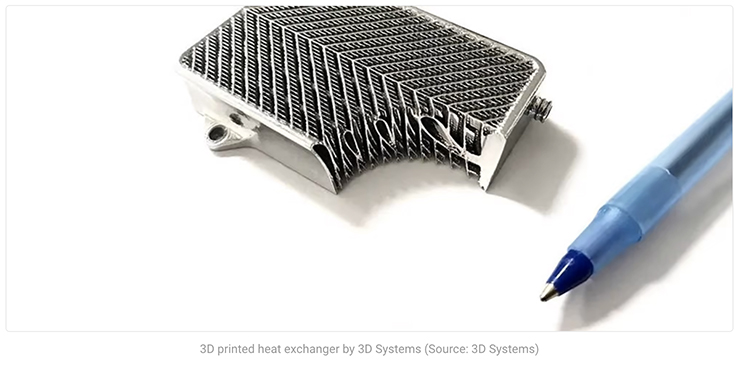

Metal additive manufacturing is as well the focus of R&D in the aerospace sector, where metal 3D printed single piece heat exchangers are being developed for the NASA and the US Army, also enhanced thanks to topological optimization, using metal 3D printers by Fabrisonic and 3D Systems.

3D printing brings indeed a series of main advantages for the production of heat exchangers, allowing to manufacture lighter devices, more compact and performing, while increasing efficiency and reliability. First of all, additive manufacturing could revolutionize the production process of heat exchangers, allowing the manufacturing of the plates pack and the manifold in a single piece, requiring no more extra steps of forming, assembly, brazing or welding. Reducing not only the production cycle time but also increasing the lightness and the robustness of the overall structure.

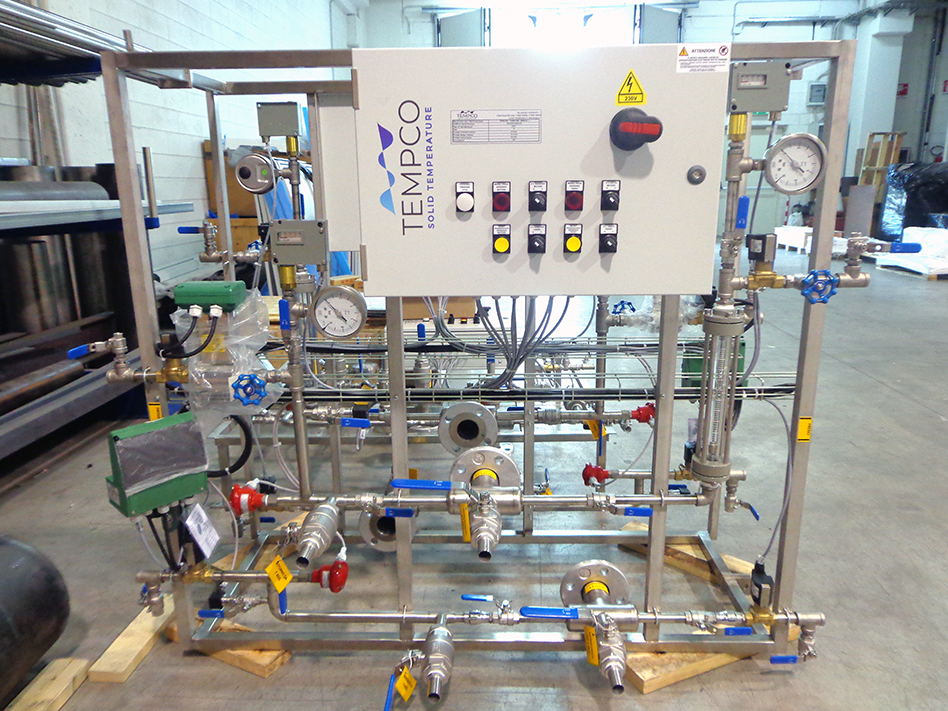

Using additive manufacturing is furthermore possible to create any imaginable kind of shape and geometry, opening a virtually unlimited design landscape for the creation of unique and customized shapes and internal geometries, also leveraging breakthrough techniques such as generative design. Also heading to the miniaturization of components and devices, aimed for narrow spaces applications which are very often required as we see in Tempco, and not just in the motorsport and aerospace sectors mentioned in the article.

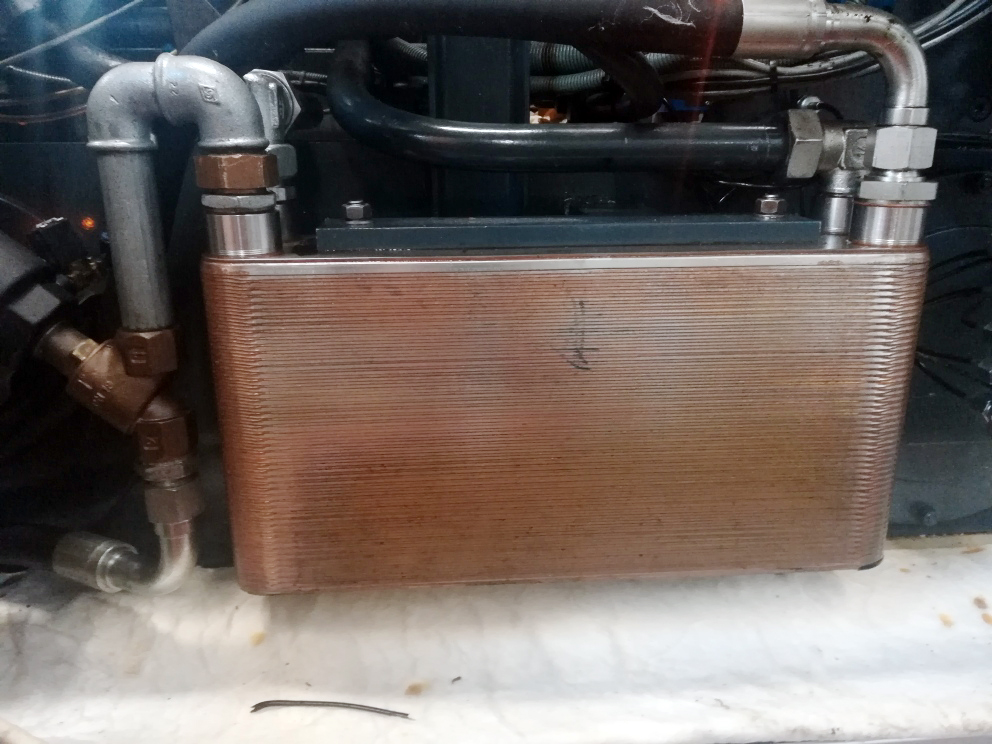

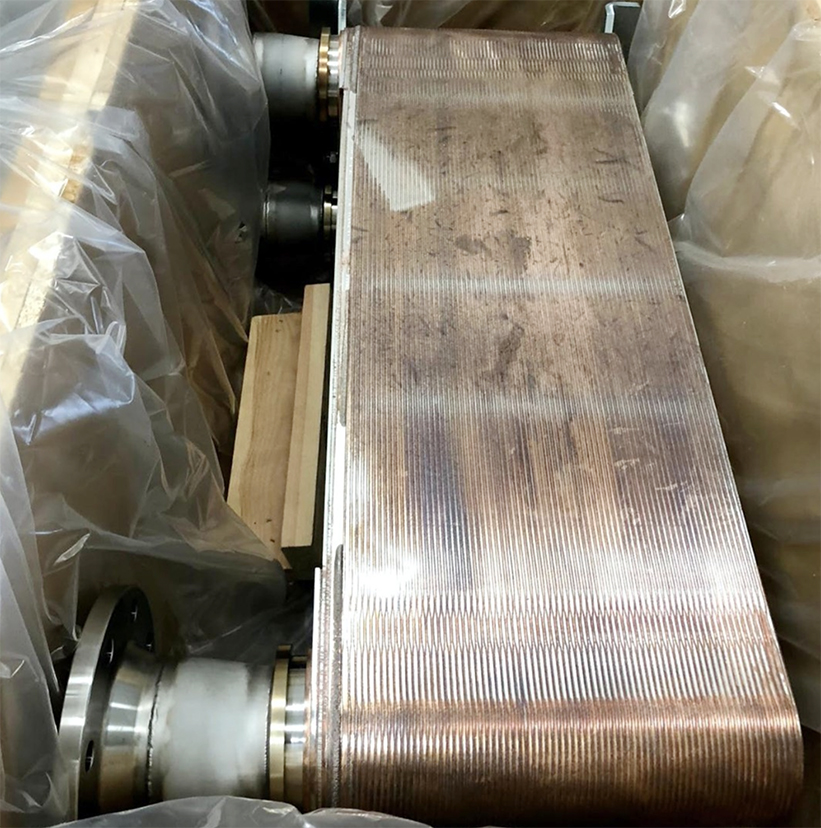

The possibility to create in AM extremely thin thermal exchange walls finally drastically increases the amount of thermal transfer surface, boosting the efficiency of the thermal machines. In addition, AM can create heat exchangers using a wide range of materials, ranging from aluminium alloys to high conductivity copper and copper alloys, and all the way up to high-temperature alloys such as Inconel 718 and Inconel 625. Eventually allowing the manufacturing of multi-material heat exchangers as showcased by the heat exchanger developed by Gen3D, a software developer for AM applications, in collaboration with 3D printers manufacturer Aerosint using laser powder bed fusion technology. This special heat exchanger combines the high-conductivity advantages of a copper alloy employed for the internal surfaces of the exchanger with those of a high strength steel on the outside.

Subscribe here to our monthly Tempco Newsletter – Solid Temperature.