Let’s speak about radiators, a very important component for the cooling of engine fluids in automotive. An interesting application of our thermoregulating units is indeed related to test bench for radiators employed within the automotive sector, and especially for high performance cars and motorsport and racing cars.

In fact, radiators employed in cars are heat exchangers aimed at cooling fluids of the engine, both water of the jackets or lubricating oil. Everyone knows the importance of the radiator, as it was also seen at the 24 Hours of Le Mans where the Ferrari #50 was hit by a stone directly in the radiator, which has been broken, damaging the radiator aimed at cooling an hybrid part of the engine and the vehicle was then forced to take a pit-stop, loosing its racing positions.

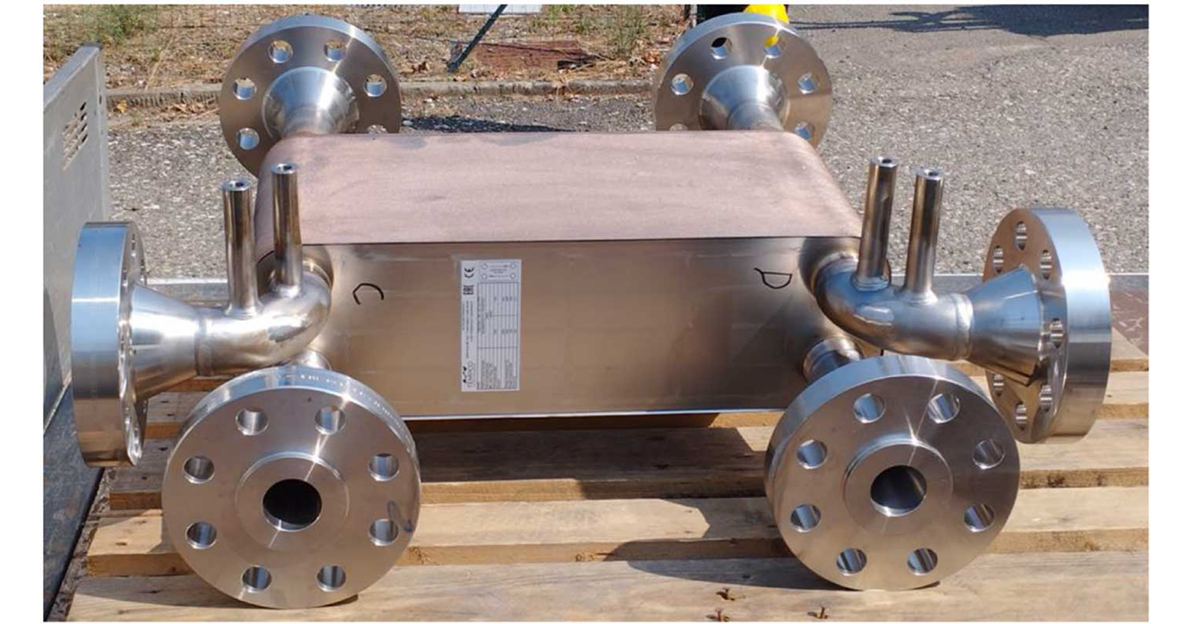

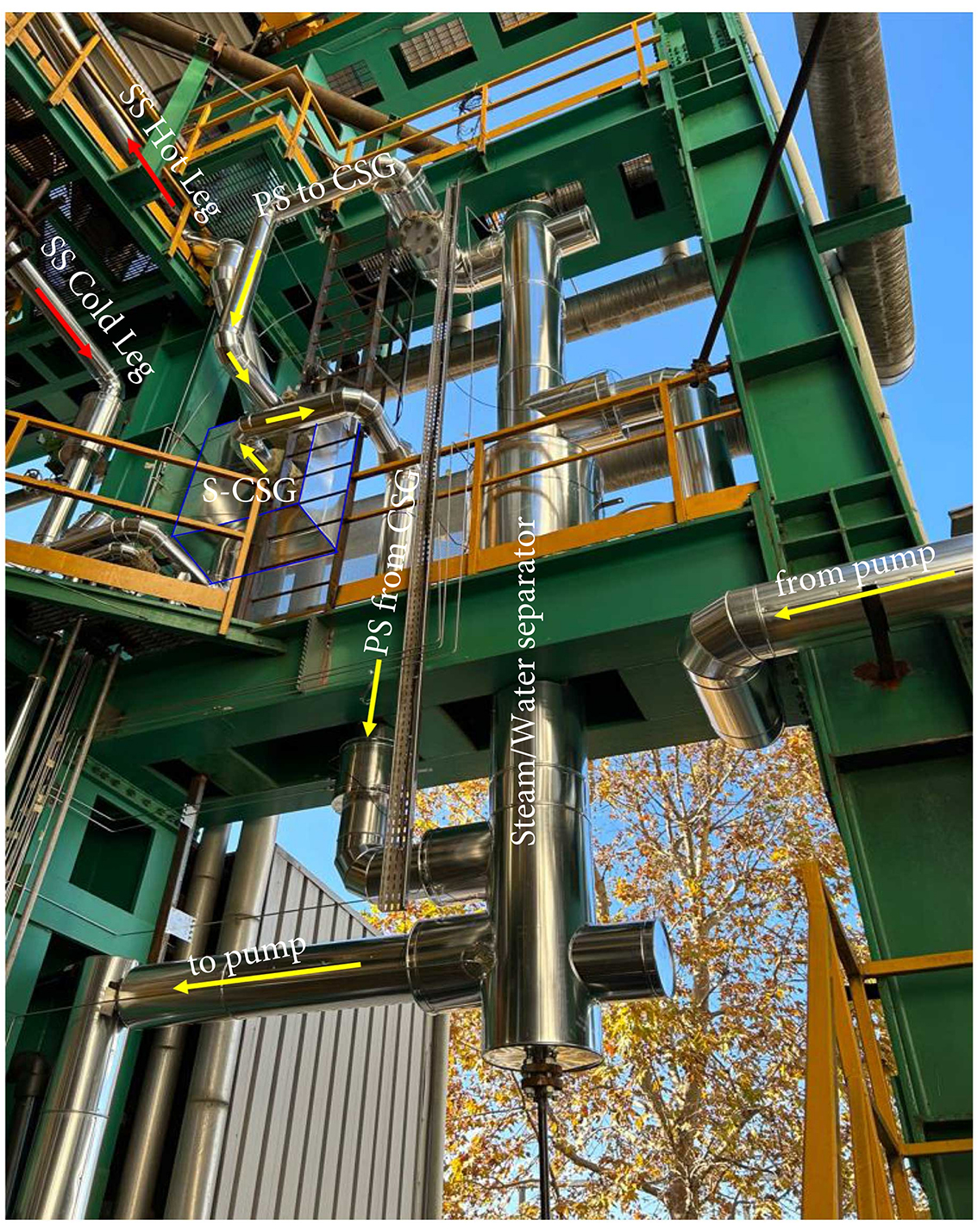

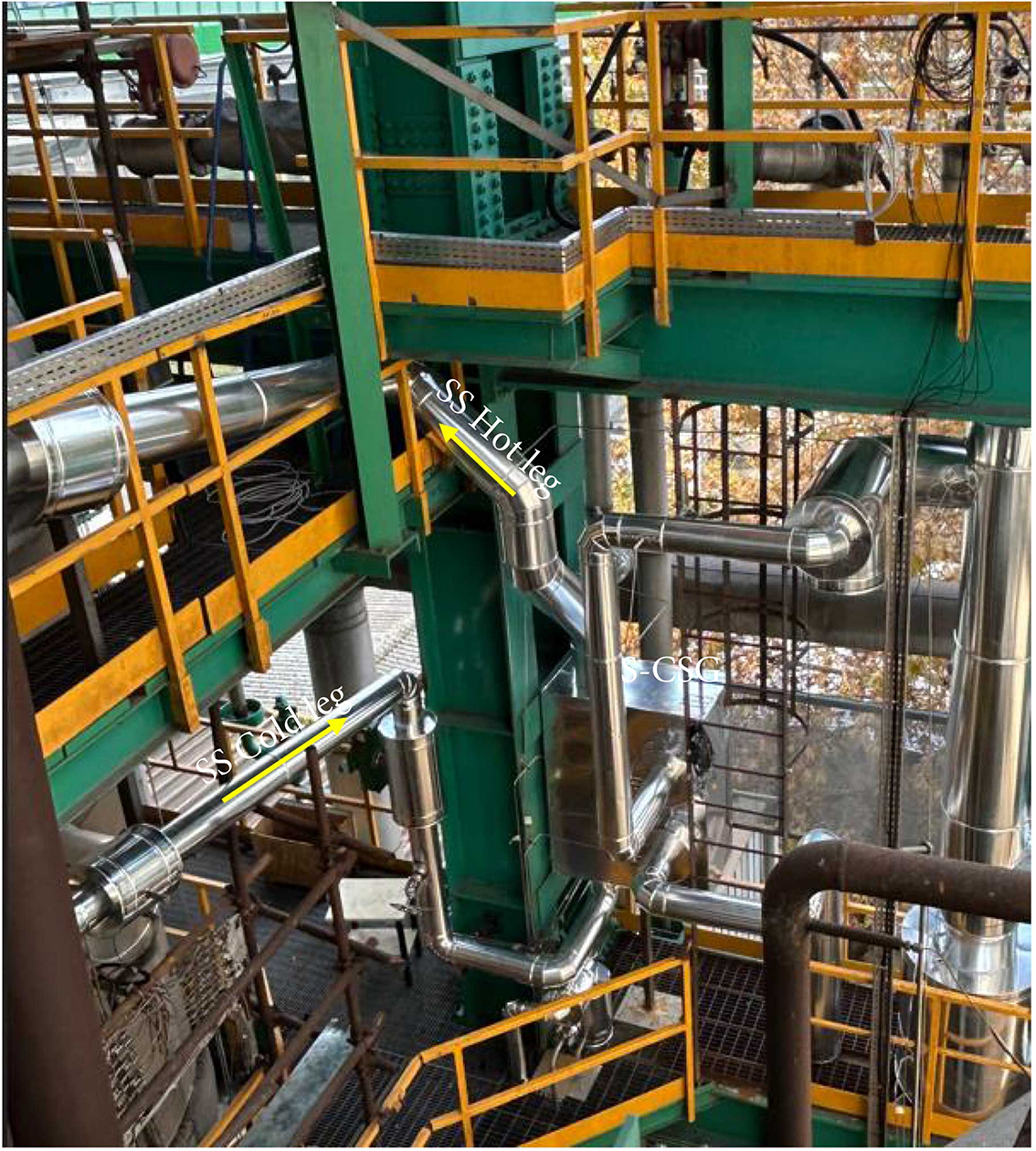

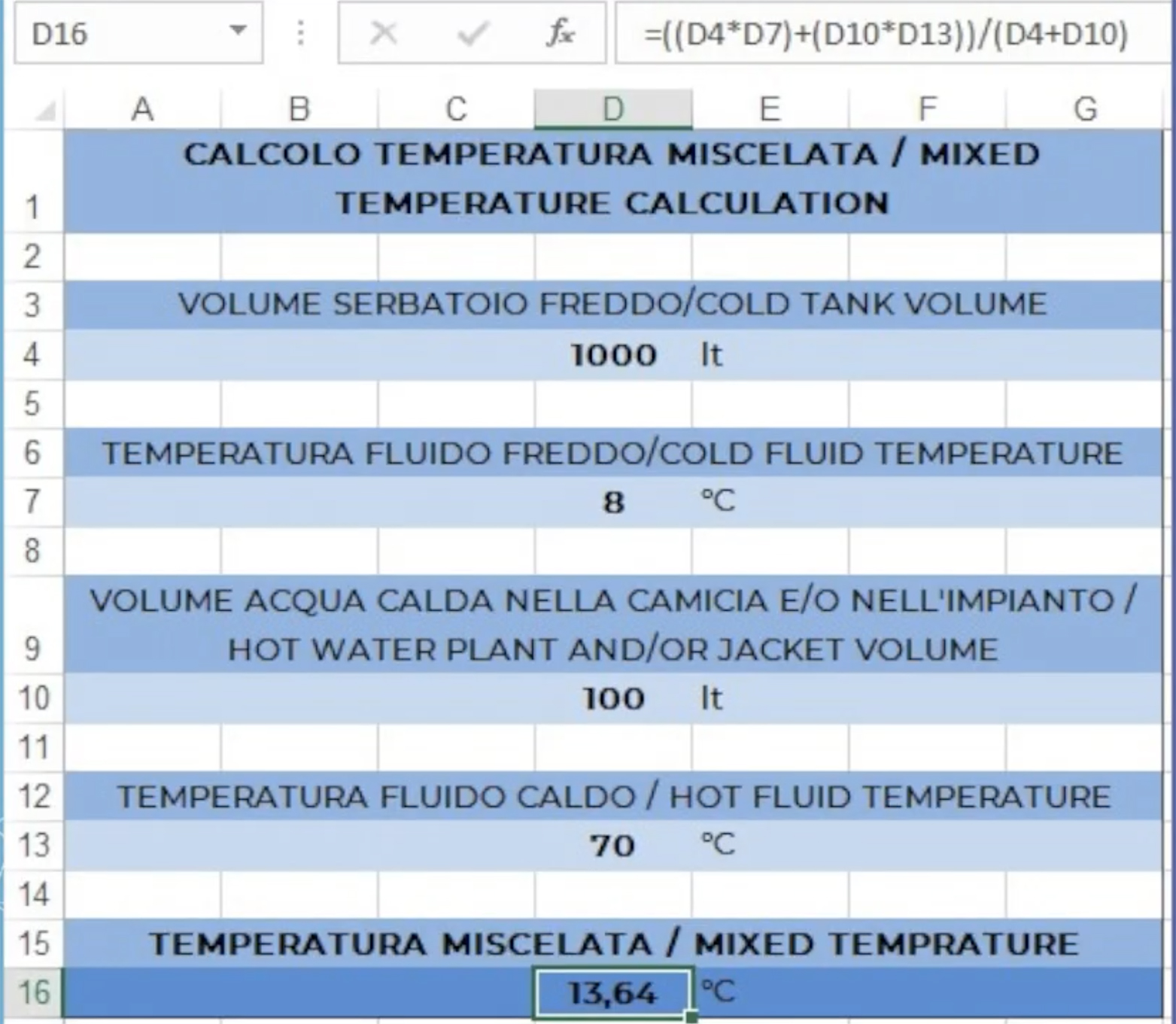

Well, our thermoregulating units are employed on test tunnels for automotive radiators, in fact for the simulation of the temperature of engine oil or of the water within jackets in order to verify the efficiency of these important components for endothermic engines. The temperature regulation is essential, because it is necessary in order to simulate with high precision the high temperature levels of the oil or of the water mixed with glycol inside the engine, with different temperature variations depending upon the conditions of use of the engine itself.