The Tempco PCHE heat exchangers (Printed circuit heat exchangers) are the focus of hydrogen applications that foster an efficient green energy transition featured in the new Hydrogen Guide 2024 by La Termotecnica. The Tempco feature details in particular a recent application we have developed for the cooling of high pressure compressed hydrogen.

This is an appointment we gladly renew, following the presence of Tempco in the last year’s edition of the Hydrogen Guide, highlighting the increasing interest and demand in the market for solutions using hydrogen as a renewable source and a sustainable green energy vector, as well as the commitment of Tempco in deploying innovative technologies enabling the diffusion of these solutions.

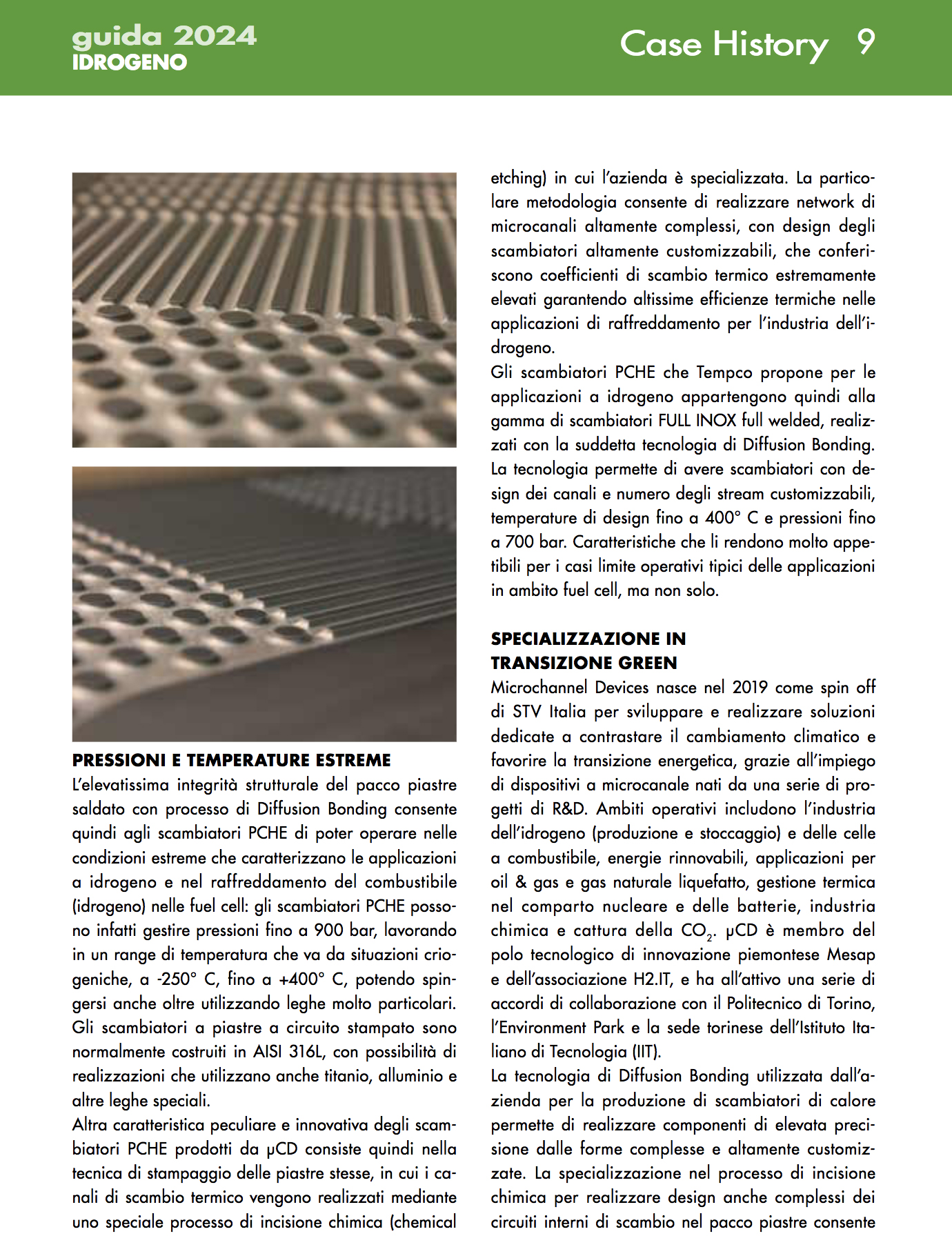

In the field of green technologies, especially important is the collaboration with our technological partner Microchannel Devices (µCD), that makes the story of the Tempco feature in the new Hydrogen Guide 2024, that designs and realizes PCHE exchangers using a special process called Diffusion Bonding. This is an innovative solid-state welding technique that allows to obtain heat exchangers’ plates stacks in a monolitich block, able to stand the high pressure and temperature levels involved in emerging hydrogen industry applications.

So we invite you to enjoy the reading of the new Hydrogen Guide 2024!

Stay updated on the latest applications of thermal energy management by subscribing our monthly Tempco Newsletter – Solid Temperature.