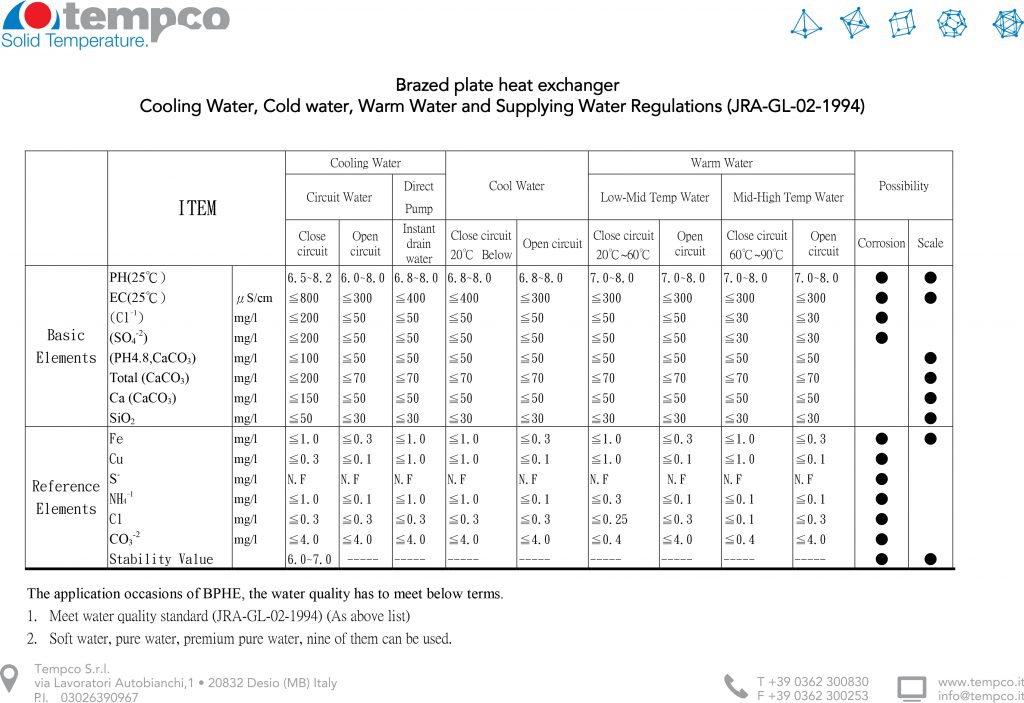

Find below a useful guideline of water quality standards in heat exchangers, compliant to the standard JRA-GL-02-1994.

Tempco Blog articles

Thermoregulating units, Tempco technical sheet updated

Thermoregulating units, updated Technical sheet for the Tempco TREG HC ST series. The thermoregulation control units by Tempco produce water at controlled temperature, in an operating range between +10 and +120°C (the range may be extended on request), with +/-1°C tolerance.

The units employ as fluids steam for the heating cycle and chilled water for cooling. Other types of fluids may also be used, following an assessment by Tempco technical department on the compatibility with the units’ components.

Thermoregulation in anesthetics production

A customer in the pharmaceutical industry placed an order for thremoregulating units intended for a new plant for the production of anesthetics. The unit is actually in the start-up phase, and works directly on the product, regulating the temperatures required in the several steps of the production of active ingredients employed in the anesthetics.

Cooling with the sunlight

At first glance it sounds like a contradiction, but this is the effect actually achieved by the innovative coating Solcold developed by an Israel-based startup.

The cooling coating employs an active cooling process involving the basic principles of laser cooling, applying the idea to the spectrum of sunlight. The coating not only reflect the sunlight, lowering the temperature of exposed surfaces and rooftops, decreasing energy consumption of conditioning systems. The solution employs the sun rays to activate a chemical process able to transform façades and rooftops in a sort of layer of ice, actively cooling them up to 10° C.

R&D in simulation models for cogeneration

Among the several offers for scholarships launched by Italian Universities, often aiming to digitalization and Industry 4.0 technologies, recently our attention has been caught by an opportunity provided by the University of Naples Federico II, for a scholarship in the ‘Development of dynamic simulation models for cogeneration plants’.

Is great to see that R&D is going on in the CHP sector, which in Italy is still having large opportunities to increase energy efficiency, with applications in the industry but also for medium-small utilities, such as SME and residential sites thanks to micro-cogeneration and microgrids.

More efficient heat exchangers in Ferrari

At the last Malaysian GP 2017, the Ferrari Team raised interest and curiosity with its SF70H, showcasing a new dynamic air intake, with ellipsoidal section obtained by combining the regular intake with two ‘ears’, increasing the intake area of the air scoop. The new design of the airbox increases the incoming air flow, in order to achieve maximum benefit from the high speed reached by F1 vehicles during races.

Heat exchangers and Fuel cells for future clean energy

Fuel cell systems are an innovative technology more and more employed in clean renewable energy applications, able to convert chemical energy from a fuel containing hydrogen into electricity. The wide range of nickel brazed plate heat exchangers offered by Tempco are an ideal solution for this kind of application, allowing space saving due to its compactness, developed in three different series in 9 different sizes.

Heat recovery in paper mill with immersion TCOIL

We recently came back to a customer after five years since we’ve supplied a heat recovery application in a paper mill. Pulp and paper mills are a challenging environment for heat exchangers, due to the presence of colloids flocs or flakes in addition to the employ of aggressive chemical bleaching agents in the water, requiring special corrosion-resistant materials.

Next generation heat exchangers in 3D printing

Additive manufacturing and metal direct 3D printing is growing fast in the manufacturing, and being also employed and tested for next generation heat exchangers. The University of Maryland is indeed developing heat exchangers produced using metal direct 3D printing to make lighter, cheaper and more efficient exchangers, achieving increased thermal transfer by 20% in heating and cooling applications.

Another great advantage of additive manufacturing is the possibility to design more efficient and complex designs, and quickly, reducing the manufacturing process from months to weeks. Leveraging on automated design algorithms is possibile to create unique shapes, aimed to increase surface thermal exchange boosting the thermal efficiency. In addition, the components are printed in a single-piece, avoiding secondary finishing processes and brazing, so that resistance to high-pressure and leakage can be strongly improved.

The return of fluid cooling in data centers

Digitization and the rapid evolution of digital technologies are bringing back fluid cooling applications in data centers and the IT sector. While in the early days chilled water was usually employed on heat rejection for big IBM mainframes, with the era of PC/desktops a real aquaphobia has grown, stating the success of air cooled systems for critical electrical components.

Nowadays, fluid cooling is strongly returning for data center applications, primarily due to the increased IT rack power density, related to the diffusion of IoT, Big data and Analytics, requiring much more efficient heat dissipation solutions. And fluid is much more efficient in heat-transfer ratios versus air. Just to give an idea, 5 years ago a rack 5Kw worth of load was a pretty high density rack, while today it can be classified in mid to low density.

Another additional benefit of fluid cooling is the better employ of space in data centers, both in terms of square footage and within each track. Fluid cooling offers companies a space-saving solution, allowing to rack and stack data centers at much higher densities than before.

Fluid cooling comes in several forms, such as rear-door application of heat exchangers, as in Tempco we’ve already installed such several solutions, employing properly shaped TCOIL heat exchangers.

Another form of fluid cooling is as mounting a heat exchanger directly onto the CPU, GPU or FPGA, extracting heat directly from the chip. It can be achieved with Novec 7000 or with regular water. Another additional solution is to remove heat by submerging servers in a tank of fluid.

And after the increase of fluid cooling in data center applications, with increasing digitalization a next-up application in the IT sector could be blockchains, cryptocurrency and fintech.