Among the several offers for scholarships launched by Italian Universities, often aiming to digitalization and Industry 4.0 technologies, recently our attention has been caught by an opportunity provided by the University of Naples Federico II, for a scholarship in the ‘Development of dynamic simulation models for cogeneration plants’.

Is great to see that R&D is going on in the CHP sector, which in Italy is still having large opportunities to increase energy efficiency, with applications in the industry but also for medium-small utilities, such as SME and residential sites thanks to micro-cogeneration and microgrids.

The cogeneration is the combined generation of electricity and heat, through the thermal recovery from engine’s water jacket and from high-temperature exhaust waste coming from a primary fuel combustion source, using heat exchangers. The primary engine generators can be an endothermic engine, gas or vapor turbines, and in most advanced solutions ORC turbogenerators, micro turbines, fuel cells and Stirling motors. Beside traditional fossil fuels, cogeneration plants also employ biogas and biomasses, as well as hydrogen in fuel cell technology systems.

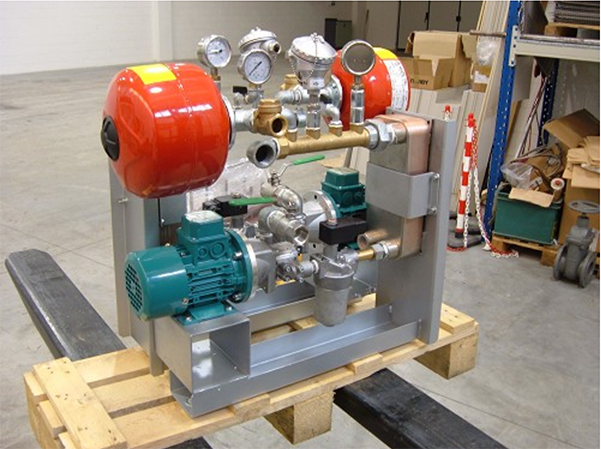

Tempco has many case histories and applications in the CHP sector, supplying equipments such as heat-exchangers/condensers, in corrosion resistant materials, high-efficiency radiators for heat dissipation and cooling towers, for evaporative condenser cooling. The Tempo range of solutions are installed in several points of the cogeneration process:

– Heat recovery units (T RECOGEN)

– Heat dissipation systems (T FIN ENGINE)

– Biogas treatment (T RECOGEN BIO)

– Biodiesel pre-heating (T START ENGINE)