Only a few years ago, data centres were synonymous with major HVAC plant installation, needed to keep computer rooms at low and controlled temperatures.

Even today it is necessary to dissipate the heat generated by hundreds or thousands of computers working tirelessly in a data centre … every time I enter the room where our small LAN server is housed, even with the heating turned off, even in winter, the air conditioning system is turned on.

The great leap forward made in recent years, is linked to working temperatures currently endured by these computers.

Let me explain. Initially, to provide air conditioning to a computer room, cooling systems that provided chilled water at the classic temperature of 7°C, with a temperature difference of 5°C (the classic 7/12°C) had to be installed

Current systems require water for direct cooling at considerably higher temperatures around 15/20°C and, as such, they are more efficient, needing to dissipate less thermal energy.

If thermal energy savings are easily understood, 100 KW is less than 120 KW, it is however more complex to understand and, for technicians, it is linked to the temperature.

In my ebook “Energia termica e processi industriali” (at the moment only in italian language) i explain:

chiller capacity increase and energy consumption decrease, if they produce chilled water at higher temperature, 15°C instead of 7°C.

This is surely a very important aspect in managing data centres. This upward shift in temperature allows you to make assessments involving choices that are definitely more green and less energy intensive.

As demonstrated by the choices made for the latest data centre installations, these complexes tend to be built in areas that provide “water at naturally low temperatures”, fjords, rivers in cold areas, icy seas, mines or the like, or in areas with harsh climates, so that so-called free cooling can be exploited.

It is precisely these applications which are becoming the key to saving energy for data centres.

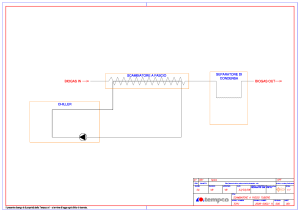

Plate heat exchangers TPLATE, free coolers TFIN are the products that we have studied and are improving to meet these new and more interesting applications.

Immersion heat exchangers TCOIL represent the new frontier in free cooling driven by data centres.

A heat exchange system, which combines management costs reduced to a minimum, high quality with unparalleled constructive flexibility. All this combined with the zero cost for main pumping.

note:

1. In essence, with the downward variance of the water temperature required, a cooling system sees its thermal efficiency reduce. Or, we can say that a cooling system that needs to dissipate a defined quantity of thermal energy, at a higher temperature, consumes less than another system that needs to dissipate the same amount of thermal energy but at a lower temperature.

For example: 100,000 Kcal/h of water at 5°C costs more than 100,000 Kcal/h at 15°C.

2. A cooling system yields more under conditions of low environmental temperature (within certain limits), compared to an installation in a warmer environment.