Digitization and the rapid evolution of digital technologies are bringing back fluid cooling applications in data centers and the IT sector. While in the early days chilled water was usually employed on heat rejection for big IBM mainframes, with the era of PC/desktops a real aquaphobia has grown, stating the success of air cooled systems for critical electrical components.

Nowadays, fluid cooling is strongly returning for data center applications, primarily due to the increased IT rack power density, related to the diffusion of IoT, Big data and Analytics, requiring much more efficient heat dissipation solutions. And fluid is much more efficient in heat-transfer ratios versus air. Just to give an idea, 5 years ago a rack 5Kw worth of load was a pretty high density rack, while today it can be classified in mid to low density.

Another additional benefit of fluid cooling is the better employ of space in data centers, both in terms of square footage and within each track. Fluid cooling offers companies a space-saving solution, allowing to rack and stack data centers at much higher densities than before.

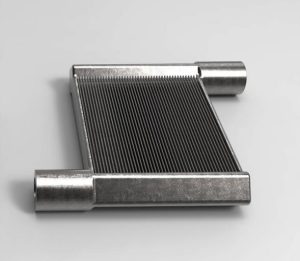

Fluid cooling comes in several forms, such as rear-door application of heat exchangers, as in Tempco we’ve already installed such several solutions, employing properly shaped TCOIL heat exchangers.

Another form of fluid cooling is as mounting a heat exchanger directly onto the CPU, GPU or FPGA, extracting heat directly from the chip. It can be achieved with Novec 7000 or with regular water. Another additional solution is to remove heat by submerging servers in a tank of fluid.

And after the increase of fluid cooling in data center applications, with increasing digitalization a next-up application in the IT sector could be blockchains, cryptocurrency and fintech.