Heat exchangers in the future are going to be less expensive, reaching thermal transfer efficiency higher than we can imagine today, due to… plastic heat exchangers!

It sounds incredible, but it can soon be achieved thanks to the work of Alberto Fina, researcher at the Turin Politecnico, who is studying conductive polymeric nanocomposites enhanced with graphene: a such important research project that recently gained founds from the Erc – European Research Council, created by the European Commission supporting excellence in research and innovation.

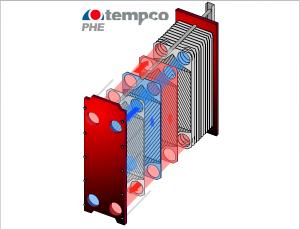

The project is called Intherm – Design, manufacturing and control of interfaces in thermally conductive polymer nanocomposites -, aiming to realize high thermal conductive polymers that could open new perspectives in the world of thermal machines and thermal energy management applications, in cooling and HVAC and heat recovery, also from low temperature waste heat flows, bringing the advantages of heat recovery and energy saving applications in a whole new range of industrial processes. These innovative plastic materials will enable to design new compact heat exchangers with costs lower than 50%, replacing traditional metals employed for thermal transfer surfaces, such as stainless steel and CU-alloys.

Also, thermal conductive nanocomposites offer the great advantage of maximum design flexibility, in addition to high processability of polymeric materials, allowing the manufacturing of special shape heat exchangers otherwise difficult to construct using traditional metals, also offering high toughness and extreme corrosion resistance.

Plastic heat exchangers are already in the phase of application study in several research project in Eu, such as the Thermonano project headed by prof. Guido Saracco, director of the Department of Applied Sciences and Technology in Alessandria branch on the Politecnico, thanks to synergies with the local factory Astra Refrigeranti, co-working since 2010 to realize polymeric heat exchangers.

Yet another application project based upon Fina studies on thermal conductive nanocomposite polymers is NanoCool, a project intended to realize high energy efficiency conditioning systems employing hybrid liquid desiccants (HDL), taking at the same time advantage of the evaporation heat of the cooling systems and the condensation heat of the chiller, using the waste heat coming from the condenser for the production and regeneration of liquid desiccants, a kind of fluids highly corrosive for traditional metals. Thanks to plastic heat exchangers offering high corrosion resistance, these kind of systems using liquid desiccants could be employed and spread onto the market, offering energy saving levels up to 65-70%, in applications for environments with high humidity.

Just to give a few more details, the Intherm project consists in the engineering of a special interface among graphene nanoparticles, with a peculiar disposition of nanoparticles in the insulating polymeric matrix, a percolant tridimensional network of highly conductive particles able to ensure an efficient conductivity. The efficiency of this new polymeric material could also be boosted by mixing graphene nanoparticles and graphite microparticles, with further costs reduction producing this innovative materials and increasing mechanical properties, such as high temperatures resistance.