Thermal systems often operate under continuous working conditions, with intense cycles and thermal load variations. Even the most robust unit, without scheduled maintenance, sees its performance decline over time: pumps lose efficiency, exchangers get dirty, valves derail from setpoints, and fluids get degraded with time and operations.

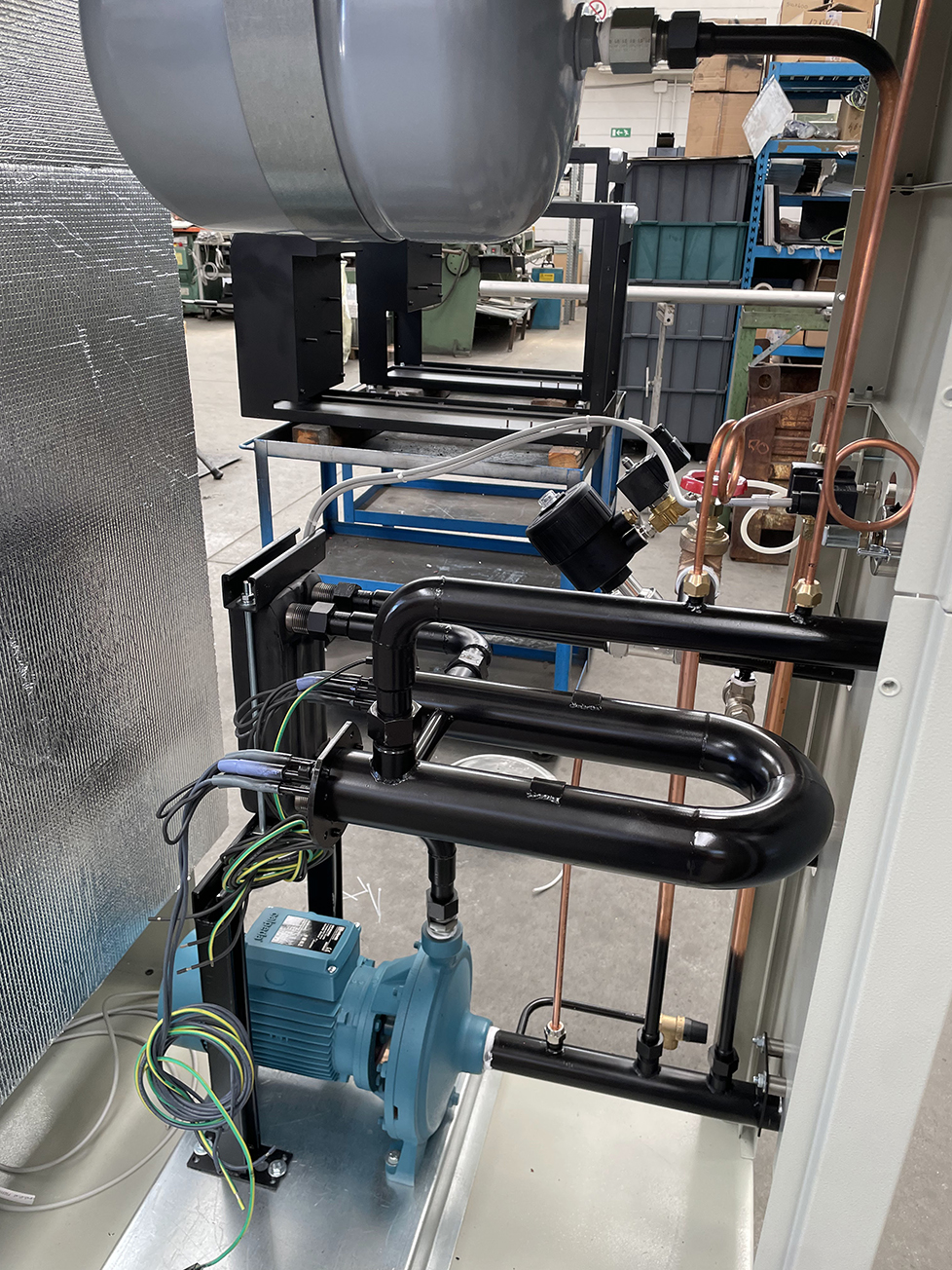

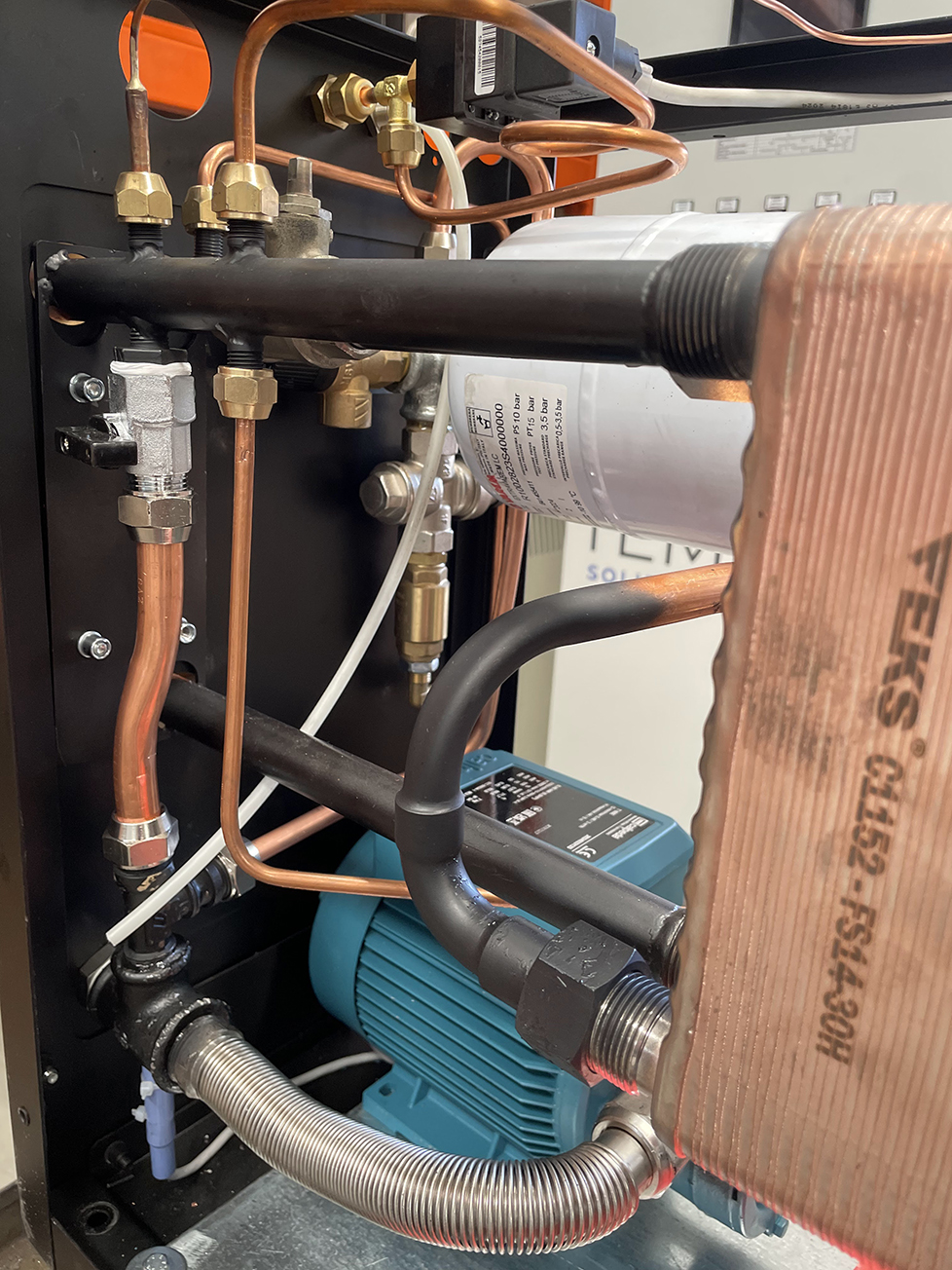

For this reason, we have been promoting the Tempco Service for years, a periodic maintenance program tailored specifically for our TREG thermoregulation units, cooling systems, thermoregulation skids, and custom control units.

The Tempco service specifically includes:

- complete check of operating parameters;

- exchanger performance verification;

- pump, valve, seal, and sensor inspection;

- heat transfer fluid analysis and recommendation for replacement;

- software updates and regulator calibration;

- advance notification of components requiring replacement.

The customer benefit is therefore very simple: zero surprises and maximum operations continuity. Scheduled maintenance allows also to:

- avoid unexpected downtime;

- keep energy consumption under control;

- extend the life of your machines;

- plan budgets and production downtime;

- have priority access to our technical support.

Service also provides an opportunity to propose upgrades or new energy efficiency solutions, such as optimizing thermal cycles or introducing more efficient heat recovery systems.

At Tempco, we therefore don’t see maintenance as a ‘cost’, but rather as an investment to ensure that thermal machines perform exactly as they did on day one, along with the opportunity to continuously improve and optimize the operational efficiency of your thermal management and temperature control systems.