The most recent developments in refrigeration and chilling solutions are aware of energy efficiency issues: chiller manufacturers have recently developed cooling units consisting in free cooler enhanced chillers, also having inverters on higher efficient modules allowing the cooling system to adjust rotating speed and power supply on compressors.

Tempco Blog articles

Carbon-ceramic brake discs

High-performance sports cars are increasingly being fitted with carbon-ceramic brake discs.

You can take a look, on 24 Hours of Le Mans, looking for the braking closed to the most challenging turn.

These brake discs are extremely heat resistant and much more efficient as a result, even in the case of braking on the very limit of grip, which can occur during sporting events or intensive use.

You may be wondering what these brakes have to do with our cooling and thermostation technologies and our heat exchangers.

Chillers on pharma applications

Our interesting customer on pharma application order to us a cooling system for pharmaceutical mixer.

It’s a small pilot plant to make some test, in next 6 months will follow the operative project.

The system is small, but very flaxible:

range of set point from -15°C up to +20°C.

Obviously thermal capacity changes, but customer accept cooling time variation in this test phases.

To avoid freeze risks, customer add to circuit the T-UNFREEZE protection:

Hydraulic turbines bearing coolers

On hydraulic power generation, TCOIL heat exchangers are a good solution to cool down the lubricating oil for turbines, with low costs and big efficency.

Dropping a TCOIL dimple plate heat exchanger into the water discharge chennel, you can cool the services on power generation units.

It’s a good way to optimize energy saving:

- low energy cost (no pump energy)

- high efficency (good thermal capacity)

- flexibility of layout

- high resistance

- low cost

This is similar to the application of data center cooling

Compressed air and plate heat exchangers

Customer needs 12 months of project and simulation in order to achieve the result:

12 brazed plate heat exchangers TCB4100 DN100 connections

In the next future Tempco skid will serve plant on 2 different features:

- cooling down of compressed air

- air fraction column recovery

Good result after pilot test plant.

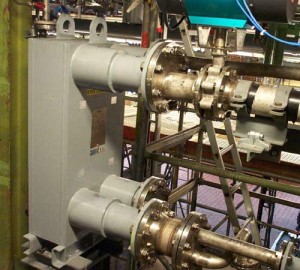

Welded Plate heat exchanger (2)

Few days ago we wrote a post on welded plate heat exchangers.

Now you can find a picture of one of that, for an industrial plant.

Selection of this solution went from a brain storming with customer:

- fluids was not suitable with copper brazed

- working temperature and pressure was not suitable with nickel brazed

- flow rate required 4″ nozzles

Solution is TWELD_TC

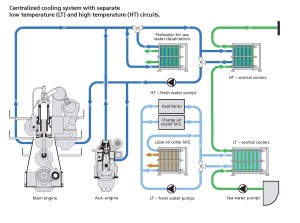

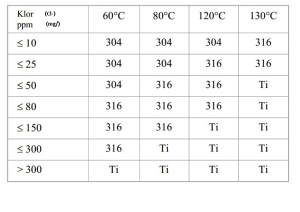

Chlorine water: titanium or stainless steel?

Chlorine water on plate heat exchangers…what kind of plate material? Our technical department answer to this question many times.

Looking at ship structure, we can think stainless steel is suitable, but you know, heat exchanger is directly in contact every time with salted water and with higher temperature sometimes.

The following data sheet gives clearly the stainless steel limits:

With sea water the must is titanium.

With sea water the must is titanium.

Brazed plate heat exchangers

Our followers know how brazed plate heat exchangers flexible are, and how many industrial application they can achieve solutions:

- flexibility

- reliability

- compactness

these features with low costs are the most important.

Market offer a lot af competitors, but everyone follows big numbers and standard solutions.

Tempco must is to customize our products in order to achieve customer needs.

Welded plate heat exchanger

Lot of industrial processes needs extreme conditions heat exchange.

In this case we are speaking about a good new: welded plate heat exchanger, fully TIG welded.

TREG FLEX energy saving thermoregulating units

Electric thermoregulating units energy saving could seem a little bit strange… It’s a custom line of our TREG skid package units.

Usually on industrial process, customers need to heat up tha batch in a short time, then keep controlled temperature along the production process.

It means max power on production starts. The following steps need less thermal energy.

Small TREG are equipped with step heating systems, controlled by manually or automatically from electronic thermoregulator.