Choosing a heat exchanger, the first and main question is: what kind of heat exchanger?

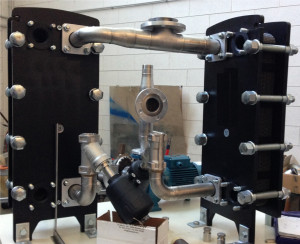

This is a topic already discussed here (mostly in the italian section, so that it represents a new contribution here), but never enough being said. Two different alternatives are indeed possible, opting for a shell and tube type or choosing a plate heat exchanger.

The progress of technology construction today allows to go for plate heat exchangers for the majority of applications, as the increasing and yet big amount of applications developed and engineered in Tempco demonstrates, in all kind of industrial sectors. In fact, if shell and tube type was almost a forced way in the past, in case of extreme working conditions with very high pressure and temperature values, new technological and engineering processes expanded plate heat exchangers potential, making them able to cover and satisfy a greater and wider range of industrial processes.

Brazed heat exchangers and all welded plate heat exchangers today allow to employ plate heat exchangers with temperatures up to 900°C, and pressures up to 100 bars. An increased range that covers almost any kind of requirement, with just a few exceptions, as for fumes recovery in refineries, or low pressure air, due to load loss and speed flow, still forcing to employ shell and tube type.

In any other kind of cooling and heating application, today plate heat exchangers are the best choice, no doubt about it, exploiting all the many advantages offered:

– higher thermal transfer efficiency

– extreme flexibility

– compact dimensions, a crucial asset in many industrial sectors

– increasing thermal transfer capacity just adding new plates

– easy maintenance and loss check and repair

– connections fixed, even in case of retrofit with a superior capacity plate heat exchanger, connections interface remains the same

The great flexibility is indeed a very important benefit offered by plate heat exchangers, representing a crucial competitiveness force allowing greater ROI: being able to increase or decrease the thermal transfer capacity simply adding or removing plates, increasing or reducing thermal transfer surface, without any intervention on piping and maintaining connections exactly the same, allows to adjust thermal capacity to the real needs and production volumes.

That means, as we use to underline, that plate heat exchangers fulfill the concept of ‘standard custom flexibility’, a leading philosophy for Tempco, allowing to develop a greater and increasing number of applications, for industrial process thermal regulation needs in a more and more greater range of industrial sectors.