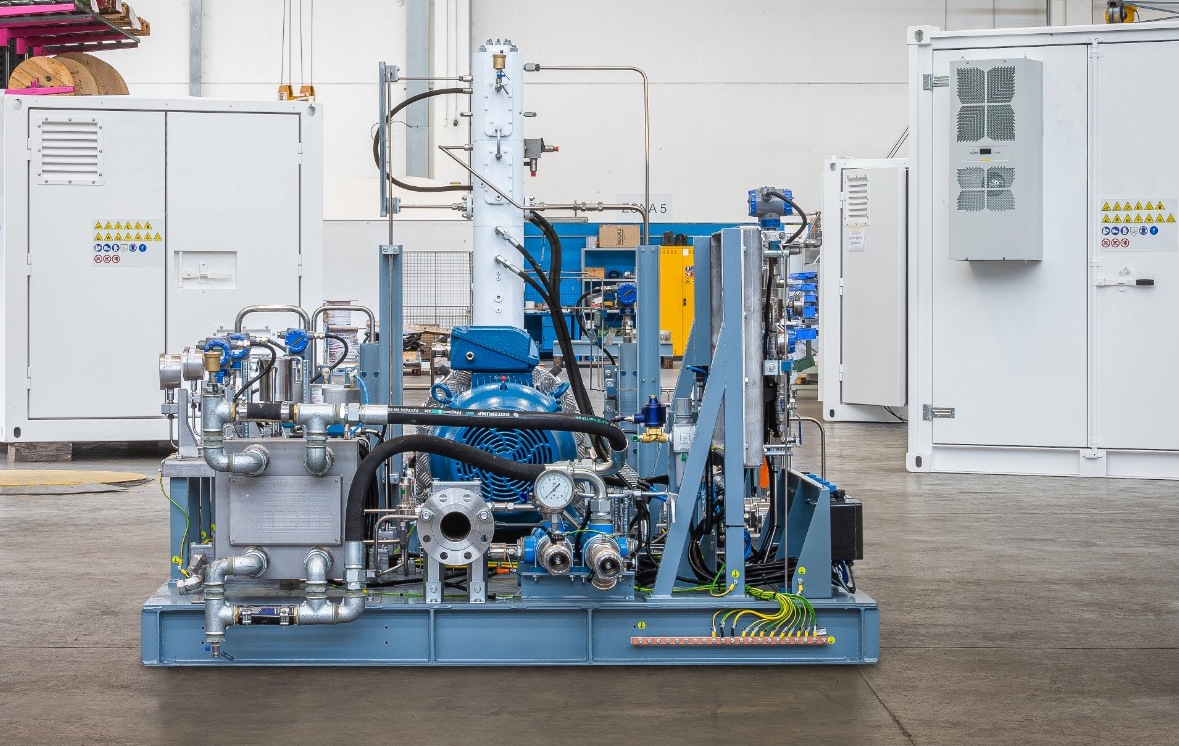

Tempco recently supplied a PCHE exchanger designed for installation on a hydrogen compressor, delivered to a major customer that manufactures alternative compressors employing highly innovative technologies and solutions for applications in compressed natural gas (CNG), biogas and biomethane production, and the hydrogen industry.

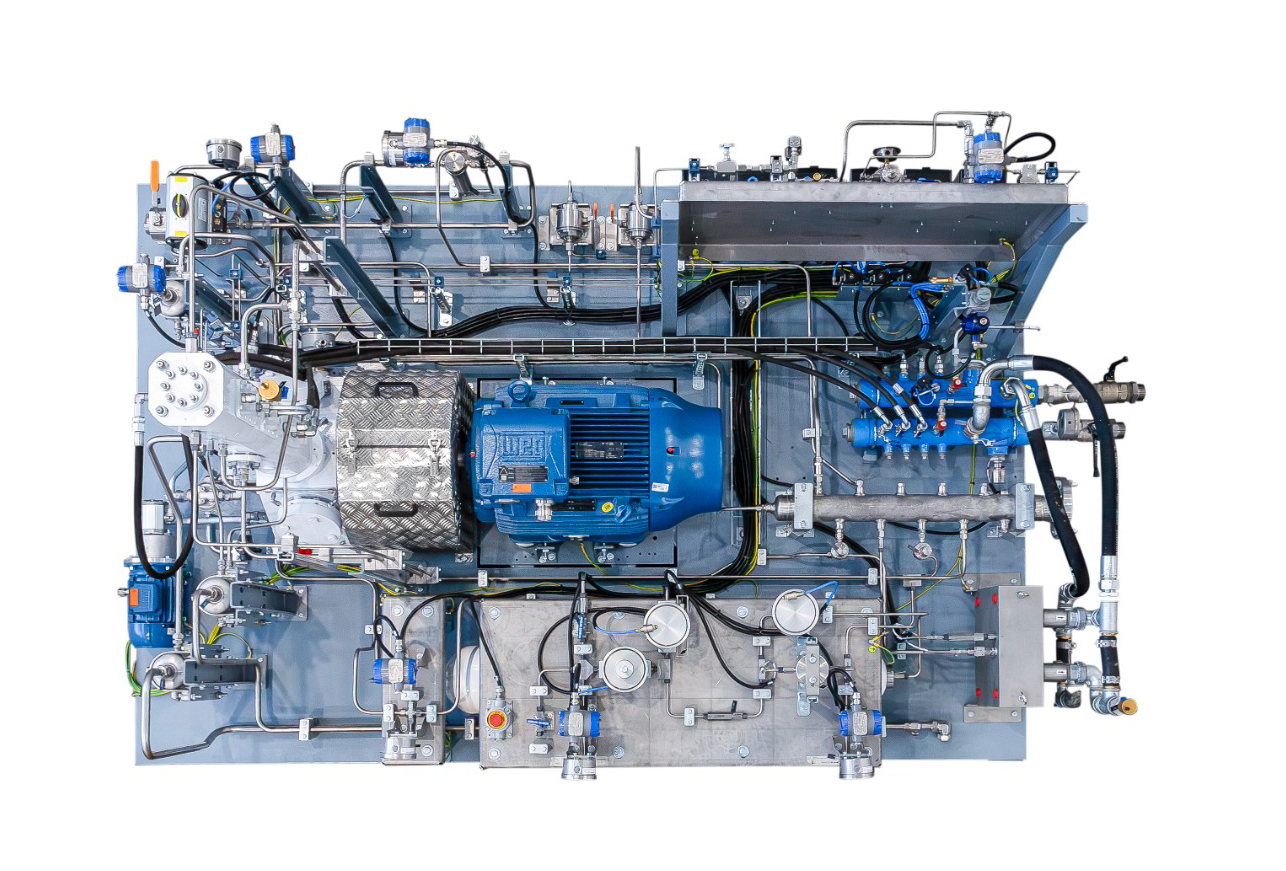

The customer’s machine is designed to compress pure hydrogen up to 450 bar g, with a special design optimized to ensure maximum performance, high gas purity, and structural integrity under extremely high-pressure operating conditions.

The unit therefore uses components suitable for gas contact and sealing systems compatible with hydrogen, designed to resist the typical effects of this gas, including permeation and material embrittlement.

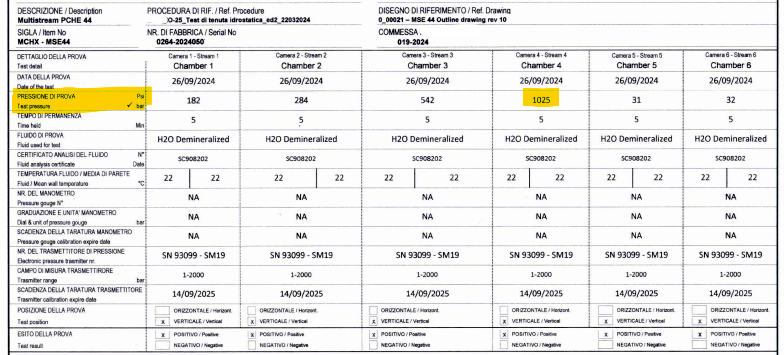

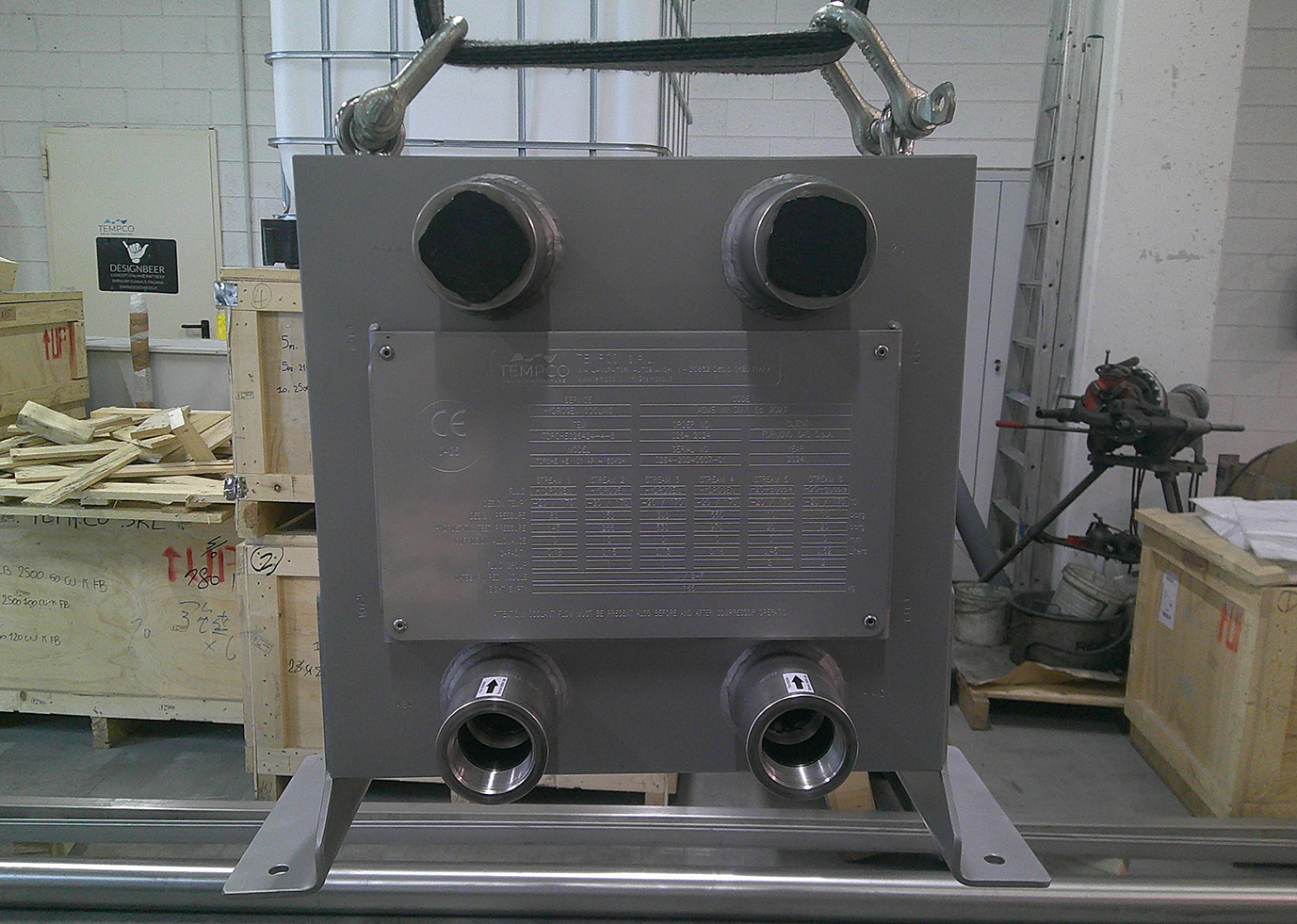

A crucial equipment among the compressor’s integrated components is the PCHE printed circuit plate heat exchanger supplied by Tempco. Thanks to its high thermal transfer efficiency, multi-stream operations allowing to manage gas cooling during multi-phase hydrogen compression cycles, and structural resistance to extremely high pressures, it offers the reliability, operational safety, and high efficiency required by the customer’s specific application.

The unit is intended for a variety of applications, from green hydrogen, electrolysis, to high-pressure hydrogen storage and injection into the grid, transportation, and hydrogen refueling stations.