Dallara is a historic Italian manufacturer of racing cars, true gems on four wheels that have shaped the history of Made in Italy motorsport over the years. The company was founded in 1972 in Varano de’ Melegari, in the province of Parma. In the high-performance world in which Dallara Automobili operates, extreme attention to detail makes the difference, and this also applies to cooling and thermal control.

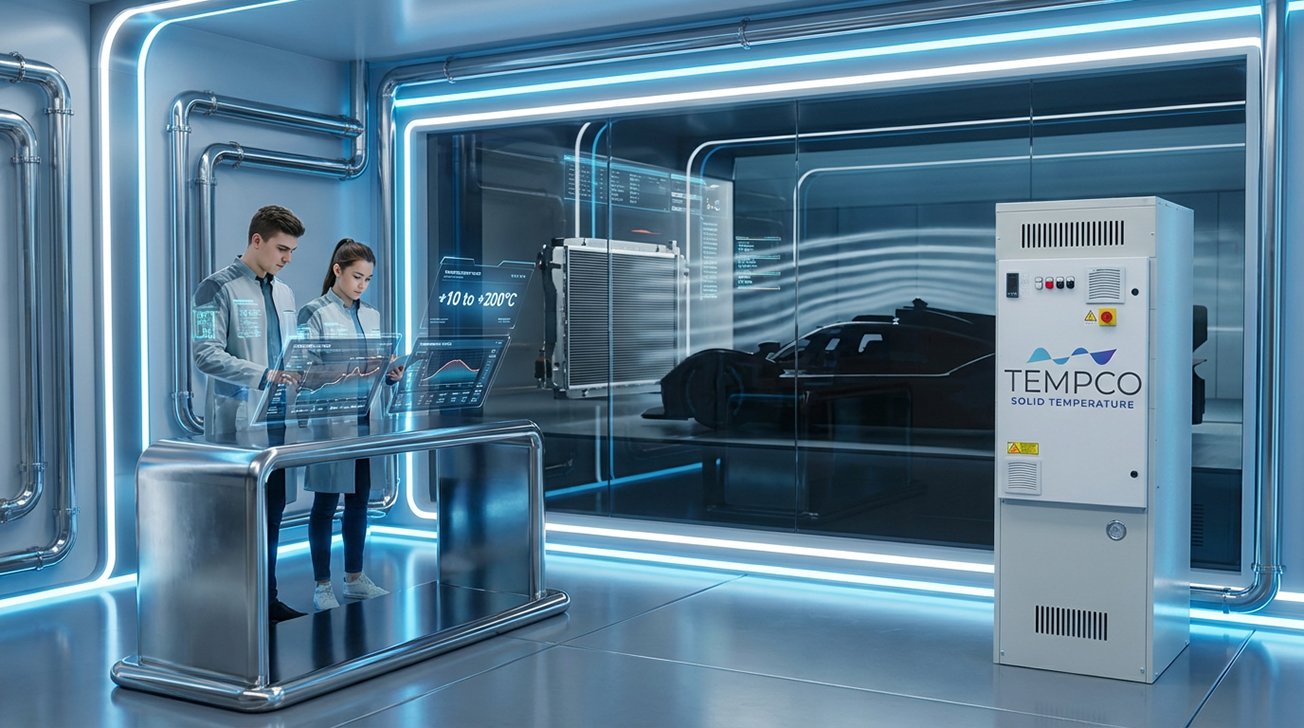

With such a prestigious reference, Tempco is very proud to have contributed to ensuring the high performance of Dallara cars, thanks to the supply of a TREG HE temperature control unit employed for radiator test benches of Dallara Automobili’s racing cars. The unit is specifically designed to heat a thermal oil circuit, operating in a temperature range of +30°C to +180°C and transferring heat to the test fluid via a brazed plate heat exchanger. The flow rate range of the test fluid is between 5 and 80 l/min.

Test benches for these components are essential for laboratory simulation of the same track conditions that the cars will be subjected to during races. Tempco’s thermal control unit is therefore meticulously designed to ensure the simulation of the thermal conditions in which the Dallara supercar radiators will operate, precisely regulating the flow rates and temperatures of the test fluid with great stability and repeatability (temperature regulation accuracy ± 2°C).

Behind every tested radiator, there is thus a control unit that ensures that every degree truly counts in determining the maximum performance of Dallara racing cars. At the heart of the test bench, the TREG HE thermal control unit uses low-specific-power resistors, offering PID-controlled temperature regulation with proportional SCRs and integrated safety logic. An electro-pneumatic modulating valve ensures the necessary heat transfer stability even at low flow rates (5 l/min), maintaining the correct turbulent flow rate on the brazed exchanger.

Finally, the system was designed to always maintain maximum efficiency in regulating the temperature of the test fluid, taking into account the strong variability of the fluid’s viscosity as the temperature varies, together with the need to contain pressure drops.