Taking care of industrial production plants means choosing original spare parts, and this is a general rule. Specifically, in thermoregulation, cooling, and energy recovery systems, each component works in synergy with the others: pumps, valves, heat exchangers, heating elements, controls, sensors. Using an incorrect or uncertified spare part can seem like a minor detail… until the day the machine breaks down.

With original Tempco spare parts, however, the customer knows exactly what they’re installing, with the peace of mind of ensuring:

- materials compatible with the process fluid;

- guaranteed performance tested on our systems;

- compliance with pressure and temperature specifications;

- long-term reliability thanks to the selection of suppliers we’ve worked with for years.

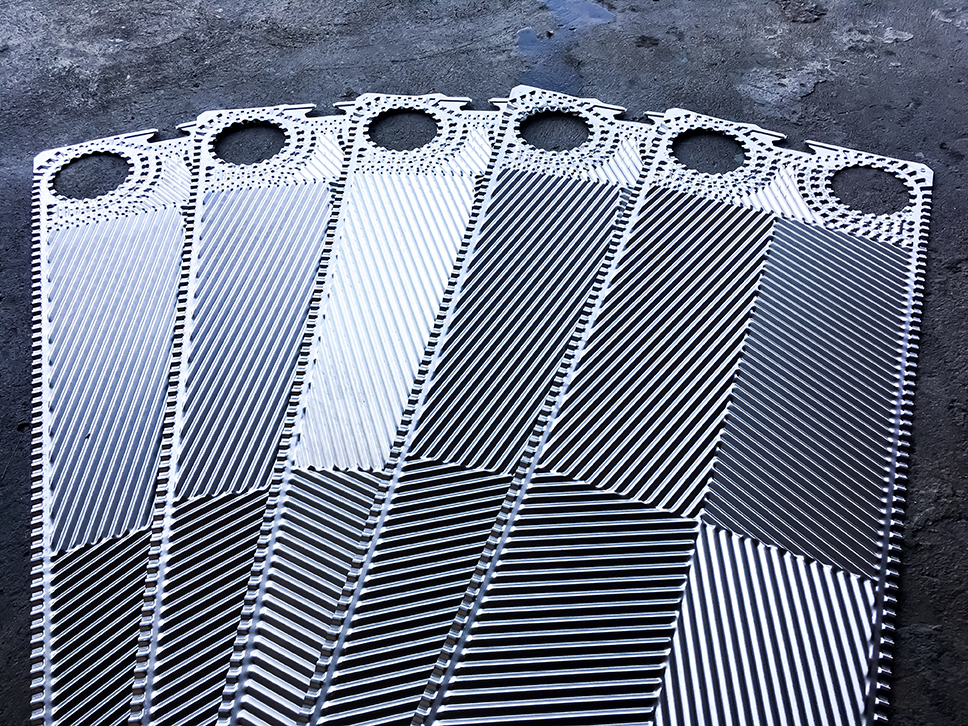

The difference, therefore, lies not only in the quality of the components themselves, but also directly impacts operational continuity: a correct gasket maintains the efficiency of the exchanger; a certified pump guarantees effective flow; consistent resistance prevents overheating or excessively frequent start-up cycles.

Furthermore, in a heating system, every deviation generates inefficiencies and hidden costs: higher energy consumption, longer rise/fall times in temperature, and micro-stoppages in production.

For all these reasons, at Tempco we always remind our customers that an original spare part costs less than a system downtime.

Tempco offers a dedicated service for the rapid supply of spare parts, even for older or custom-built machines. Keeping your systems in ideal condition thus means preserving their useful life, ensuring consistent performance.