In the food and pharmaceutical sectors, reliability and cleanliness of the production process are essential. To meet the needs of companies operating in the food and pharma sectors, Tempco creates a series of custom-designed thermoregulation units for machine and plant manufacturers (OEMs) who need to precisely manage process water temperatures, ensuring stability and repeatability over time.

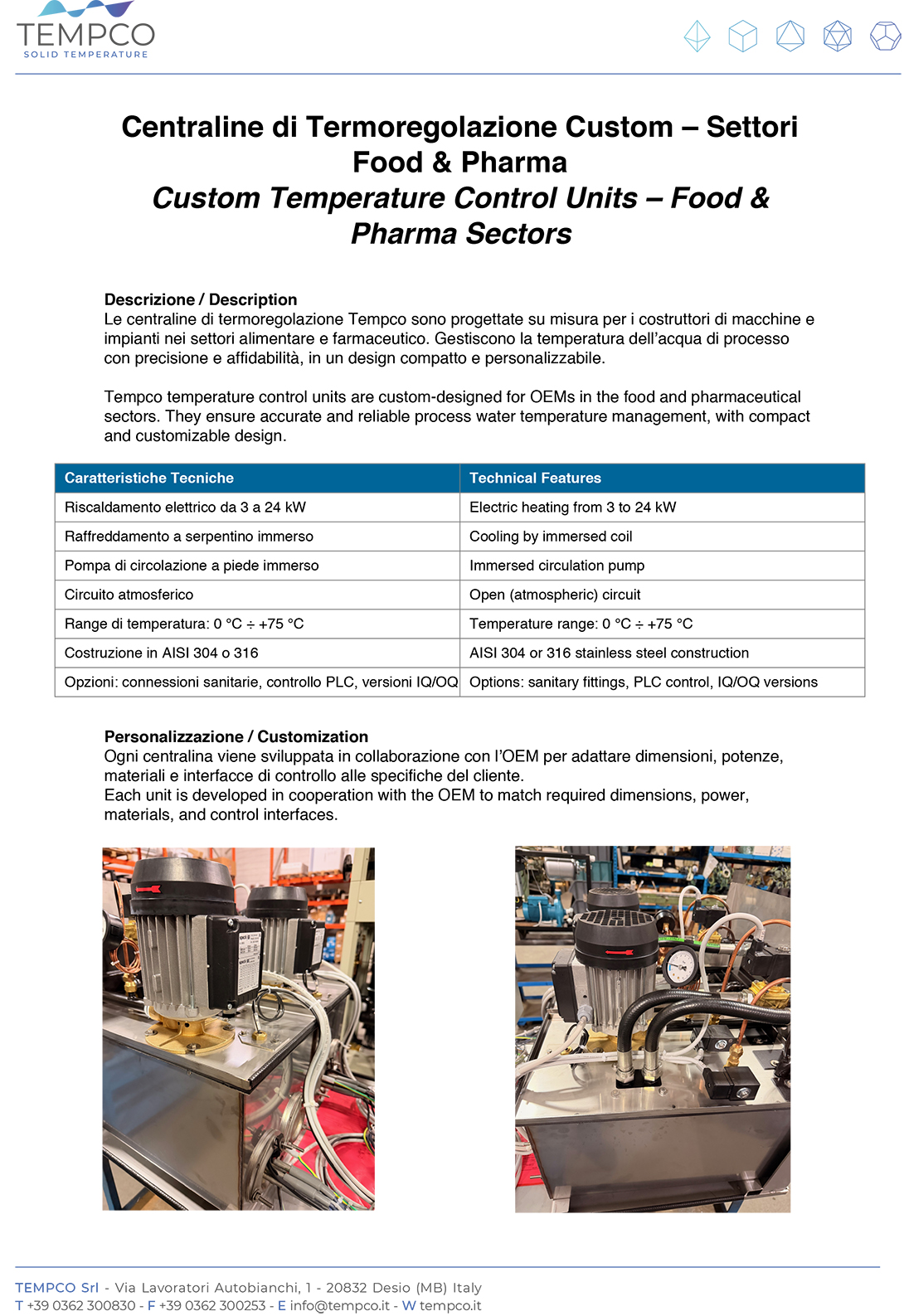

These compact units are designed with custom dimensions for integration into the customer’s machine structure. Each version is configured based on application specifications: electric heating with resistances from 3 to 24 kW, forced circulation via a submersible foot pump, and cooling via a submersible coil connected to an industrial water circuit or external chiller.

The circuit is atmospheric, with a stainless steel tank, designed to ensure maximum hygiene and ease of maintenance. The recommended operating temperature range is 0/75°C, ideal for washing, mixing, or thermal conditioning of process fluids.

Versions for both the pharmaceutical and food & beverage sectors feature materials and components compatible with wash-down environments and, upon request, sanitary clamp or DIN connections. Versions with remote control options via PLC, analogic signals, or fieldbus (Modbus, Profinet, EtherNet/IP) are also available.

These solutions offer OEMs the ability to easily integrate a complete, compact, and reliable thermoregulation system, reducing development times and ensuring an efficient thermal management of the production process. As always, each project begins with a technical consultation with the customer, to tailor dimensions, materials, power, and control logic to the specific needs of the system.