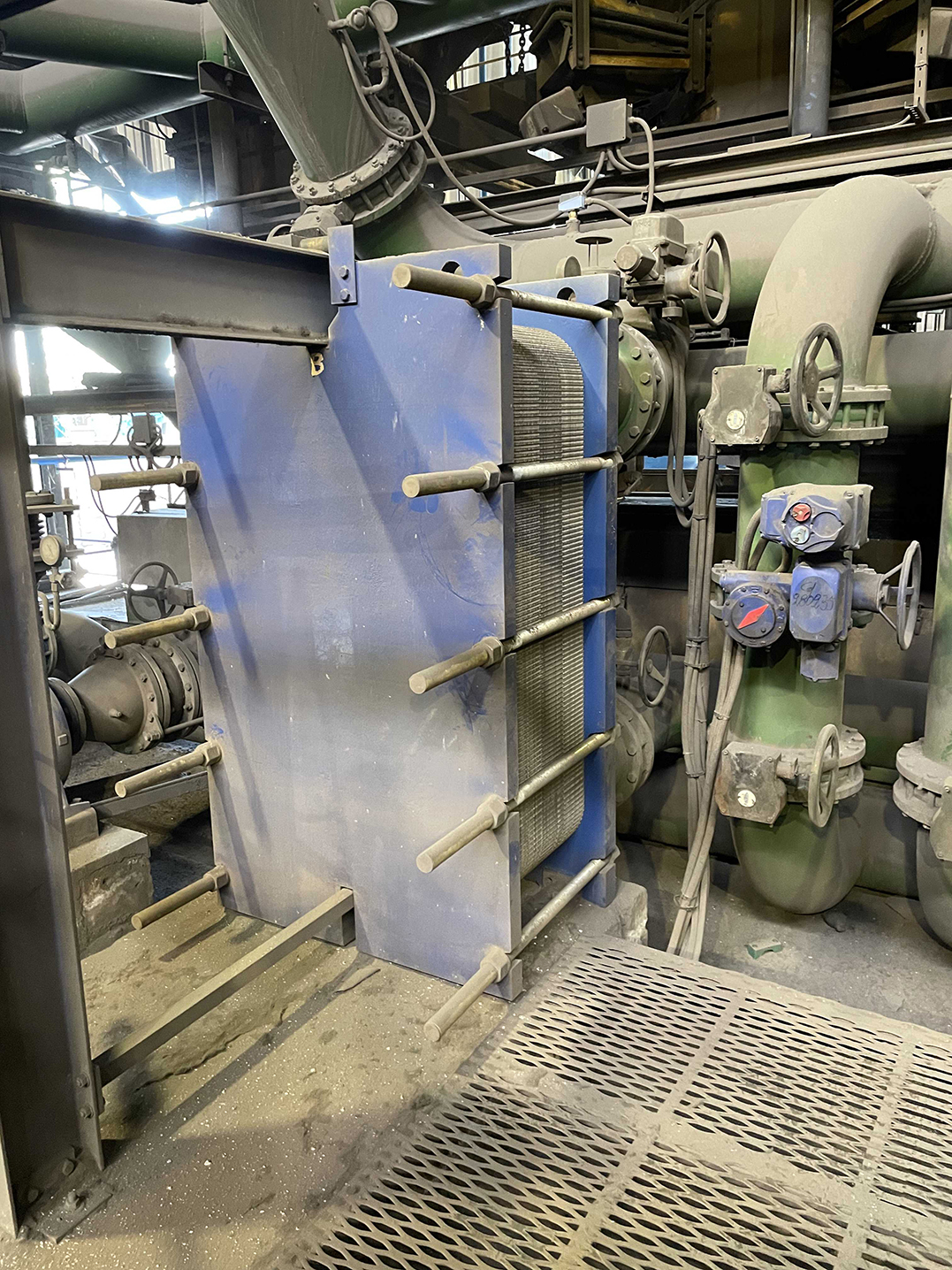

For an important steel mill in the province of Milan, we have recently completed the revamping of a series of plate heat exchangers. The intervention involved exchangers with DN250 connections and overall required the cleaning of more than 1.500 plates.

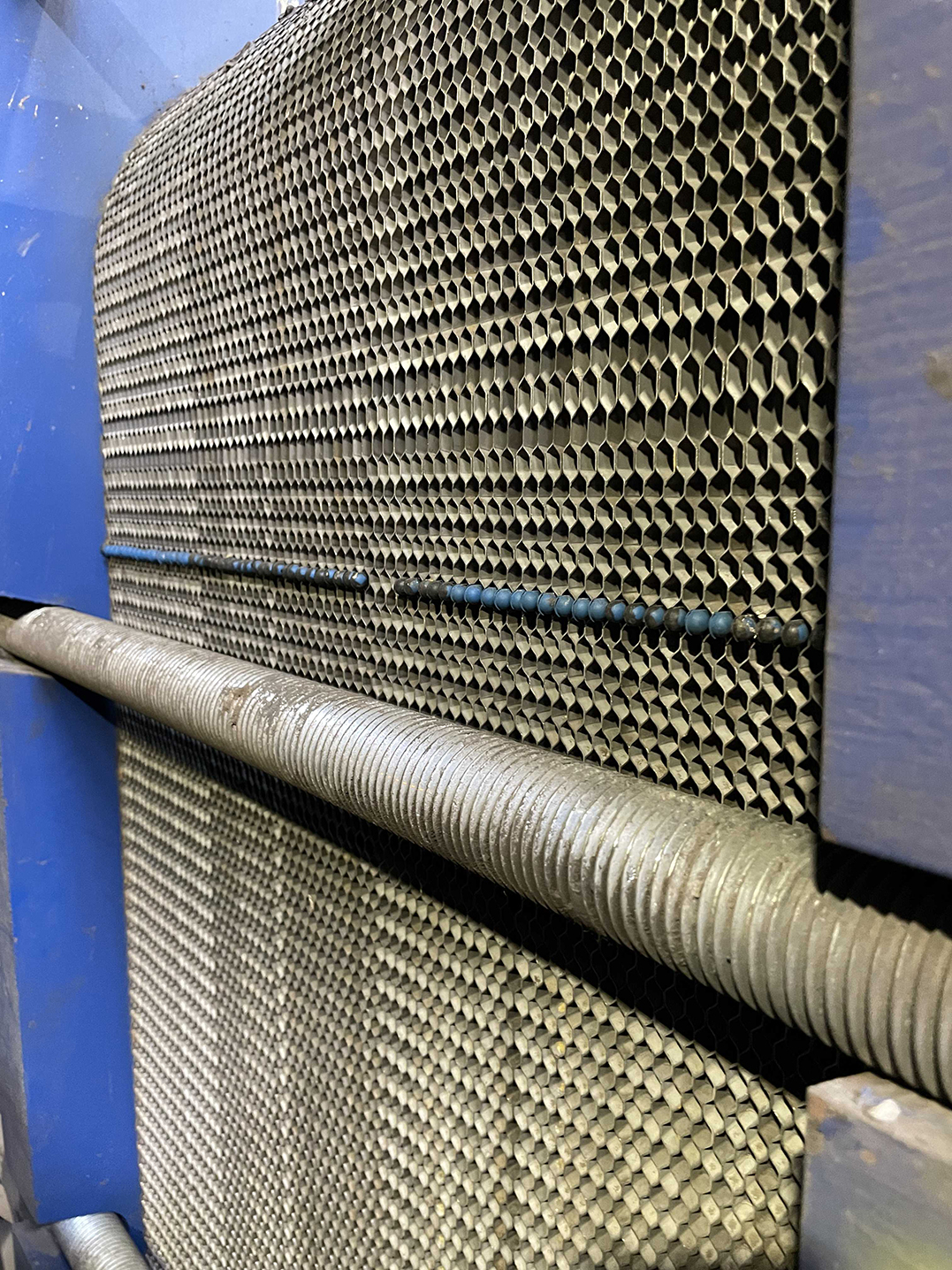

For some of the most obsolete models of heat exchangers in use at the customer’s production plant, after a survey completed with the collaboration of the maintenance office, it was decided to proceed with the complete replacement of the plate packs.

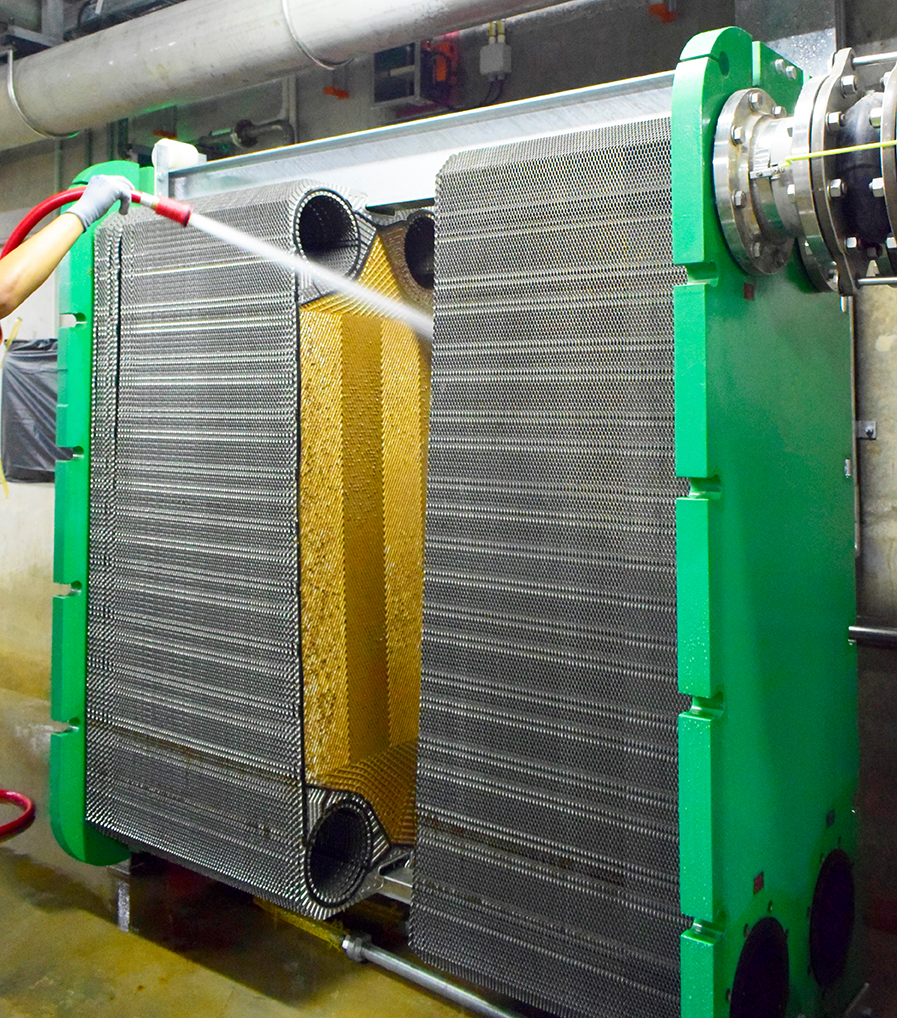

Other more recent exchangers have instead been completely regenerated by washing the plates and replacing the gaskets. The operation was completed within 3 months, taking advantage of the downtime of the production lines in alternating phases, in order to allow operational continuity for the customer and to bring the exchangers back to full thermal transfer efficiency.