Brazed plate heat exchangers represent an extremely compact and efficient solution for heat transfer applications where space is limited and high performance are required. The standard version of these exchangers is designed for operating pressures up to 30 bar, but for more demanding applications, Tempco offers special high-pressure versions, with models capable of reaching 70, 100, and up to 140 bar design pressures.

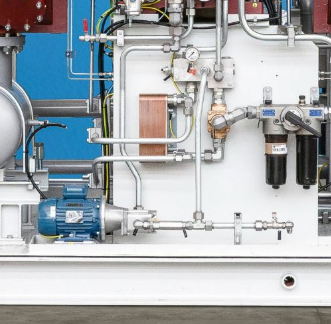

One of the most common applications for high-pressure exchangers is gas cooling in compressors, as shown in the photo below: a high-pressure compression system for technical gases, where the exchangers are used to dissipate the heat generated during compression. In these systems, robustness and mechanical sealing are essential to ensure safety, continuity of service, and longevity.

Therefore, these are some of the main advantages offered by this special type of high-pressure brazed exchangers:

• Compact design and simplified installation

• High mechanical resistance, up to 140 bar

• No routine maintenance thanks to the absence of gaskets• High heat exchange efficiency even at low flow rates

• Customized versions available for specific gases, oils, or process fluids

The high-pressure versions of brazed exchangers are also used in heat recovery systems, CO₂ hydraulic circuits, HVAC systems for transcritical refrigerants, and in the hydrogen sector, where operating conditions require absolutely reliable equipment.