In steel rolling processes, temperature plays a fundamental role in the quality of the finished product and the efficiency of the entire plant. An often overlooked, yet crucial, aspect is preheating the rolls before starting the rolling process. Tempco manufactures electric heating units specifically designed for this application, ensuring optimal performance and longer component life.

Why preheat rolling rolls?

- Thermal shock reduction. Rolling rolls are subject to rapid temperature changes when they come into contact with the red-hot metal. Adequate preheating reduces thermal stress, preventing cracks, deformations, and premature wear.

- Increased dimensional stability. Temperature variations affect the expansion of the rolls, potentially causing misalignment and defects in the rolled product. Maintaining the rolls at a uniform temperature before starting the lamination process ensures more precise rolling and reduces production waste.

- Product surface quality. A roll with uneven temperature can cause imperfections on the surface of rolled steel, such as marks or waviness. Preheating ensures more uniform contact and a high-quality finishing.

- Optimized energy efficiency. Without preheating, the initial contact between the cold roll and the hot metal leads to heat dissipation and increased energy requirements to maintain the suitable operating temperatures. Preheating units reduce this heat loss, improving process efficiency.

Tempco Solutions: Electric Heating Units

Tempco designs and manufactures electric heating units specifically for preheating rolling mill rolls.

These systems offer:

- Precise temperature control, with automated adjustment

- Uniform heat distribution, avoiding temperature differences along the roll

- Reduced start-up times, increasing plant productivity

- Compact and efficient design, with customized solutions based on customer needs

The adoption of Tempco control units therefore represents a strategic investment for rolling mills aiming to improve reliability, product quality, and operational sustainability.

Steel, rolling, rollers, finishing, solid temperature, temperature control, automation, reliability, steel industry, heating, preheating, heating units, Tempco, surface quality, dimensional stability, energy efficiency, energy saving, operational efficiency,

Illustrative image of the steel rolling process where preheating of the rolls is essential.

Image showing a heating unit for preheating the rolls in steel rolling.

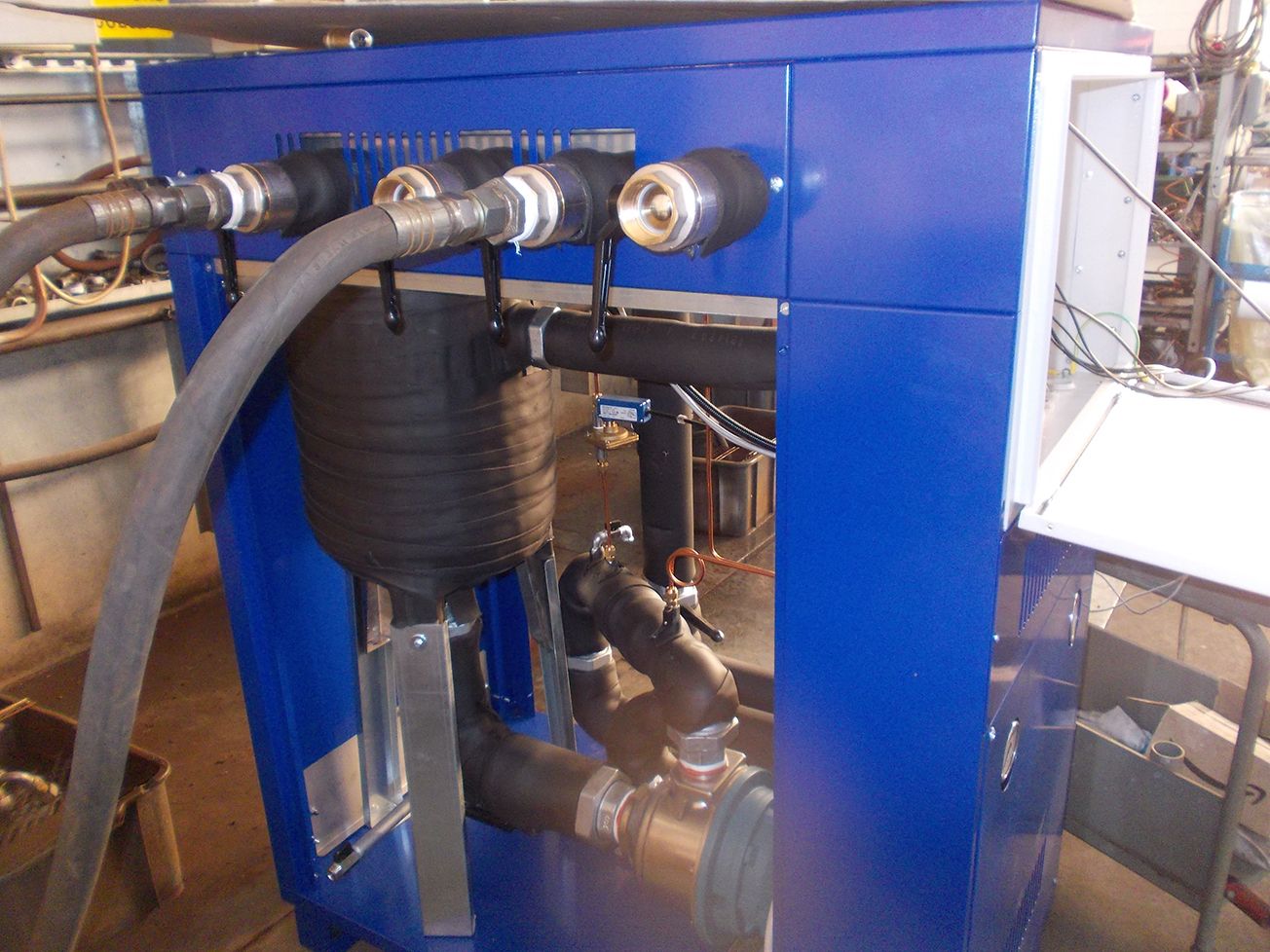

Image showing the connections in a heating unit for preheating the rolls in steel rolling.