The image below shows a new three flow PCHE excganger (printed circuit heat exchanger) for hydrogen compressors that we built for a new order. Specifically, it’s a hydrogen refueling station in Monfalcone, where three PCHEs will be installed, serving both heavy-duty and light-duty vehicles.

This important new order for Tempco confirms the growing attention this innovative type of heat exchanger is attracting. Therefore it leads to a broader reflection on the concept of a holistic approach to heat transfer systems. In fact, nowadays it’s necessary to go beyond the evaluation of the mere initial cost of a heat exchanger, as industrial thermal engineering involves a series of more complex challenges.

There are many factors to consider:

- Energy efficiency

- Installation space and compactness

- Reliability

- Ease of maintenance

- Reduced start-up times

- Sustainability of the investment

Given all these requirements, limiting the assessment solely to the economics of the initial cost of the equipment risks to provide a too narrow perspective. A holistic approach to thermal transfer systems is therefore needed, taking account of the entire life cycle of the system. This approach should consider not only the technology’s purchase cost, but also operating costs, potential system downtime, energy efficiency, and integration flexibility.

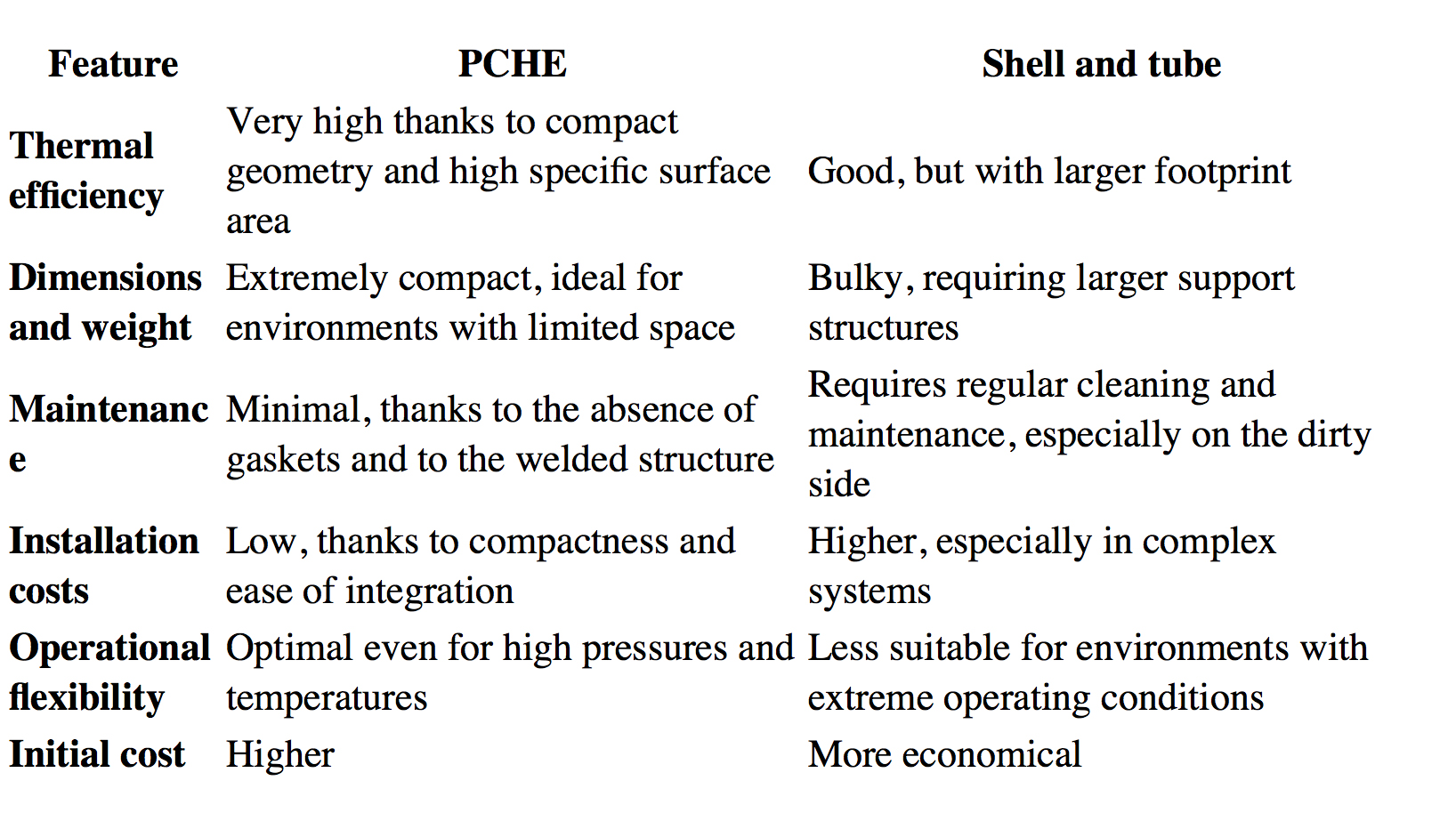

PCHE vs. Shell and tube: a comparison beyond price

A prime example is the comparison between PCHE exchangers and traditional shell and tube exchangers. At first glance, PCHEs may seem less competitive in terms of initial cost of the unit. However, a holistic analysis reveals a somewhat different picture:

Value is measured over time

A holistic approach therefore also includes considering the overall return of investment (ROI). Thanks to their high heat transfer efficiency, PCHEs reduce energy consumption and improve the overall performance of the production process they serve. In many cases, the initial cost pays off in just a few years, especially in sectors where every percentage point of efficiency makes a difference (hydrogen, cryogenics, power-to-gas, fine chemicals). Furthermore, in modular projects and applications where compactness and safety are crucial (such as hydrogen refueling stations), PCHEs represent the only possible technical solution.

Therefore, choosing the most suitable technology for a given application means looking beyond the initial purchase price. It means adopting a holistic view that takes into account the entire life cycle of the system, and not just the cost of the equipment. From this perspective, PCHEs, although more expensive to purchase, offer superior and sustainable value over time, making them the strategic choice for those looking forward to the future.