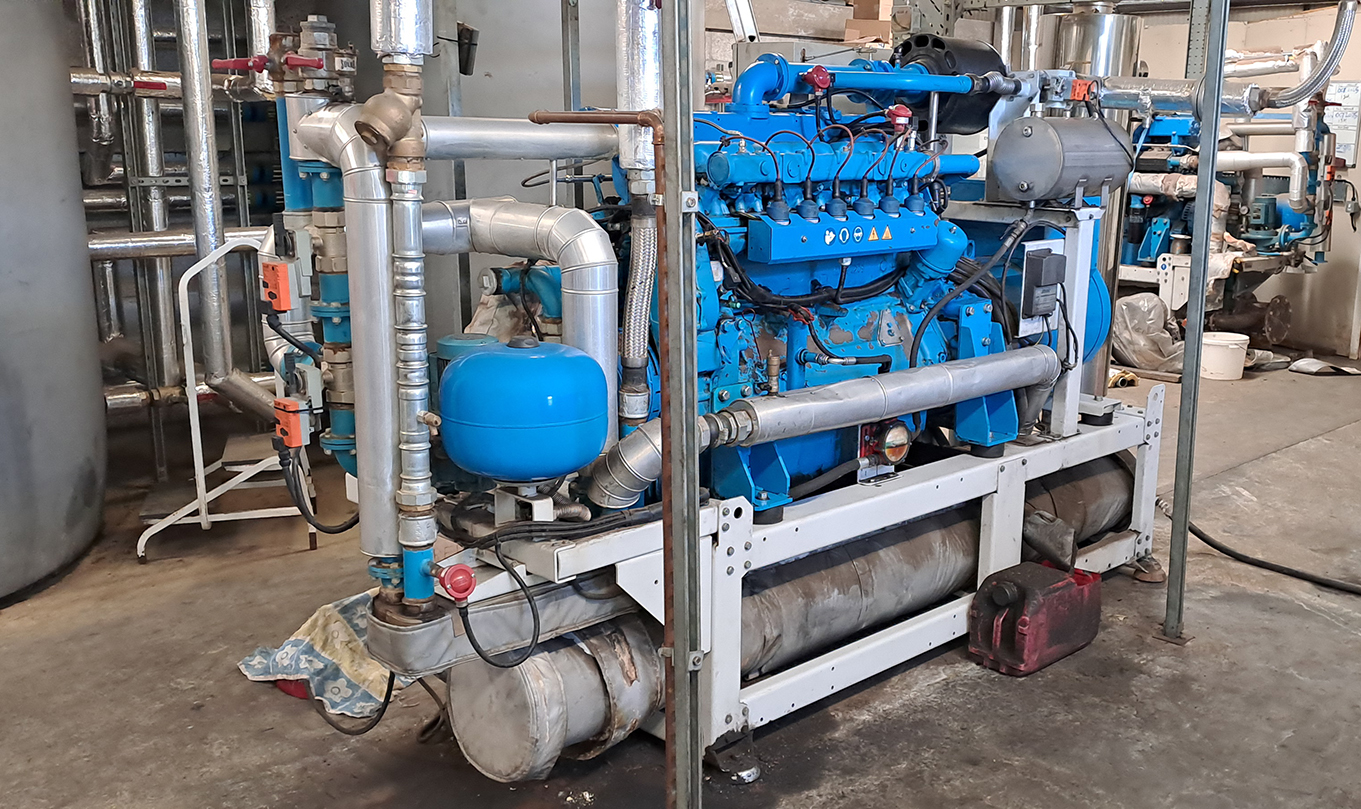

In the images of this post you can see a cogeneration system realized by Tempco and that has been in operation since 2014, equipped with our heat exchangers.

Cogeneration plants involve different applications for heat exchangers, as they allow to further increase the efficiency of the process. The use of heat exhangers in cogeneration starts from the pre-treatment of the biogas, an operation aimed at eliminating the impurities and humidity present in the biofuel to preserve the engine, up to the heat recovery from the exhaust fumes of the engine itself using shell and tube exchangers, maximizing the amount of thermal energy that the system can generate.

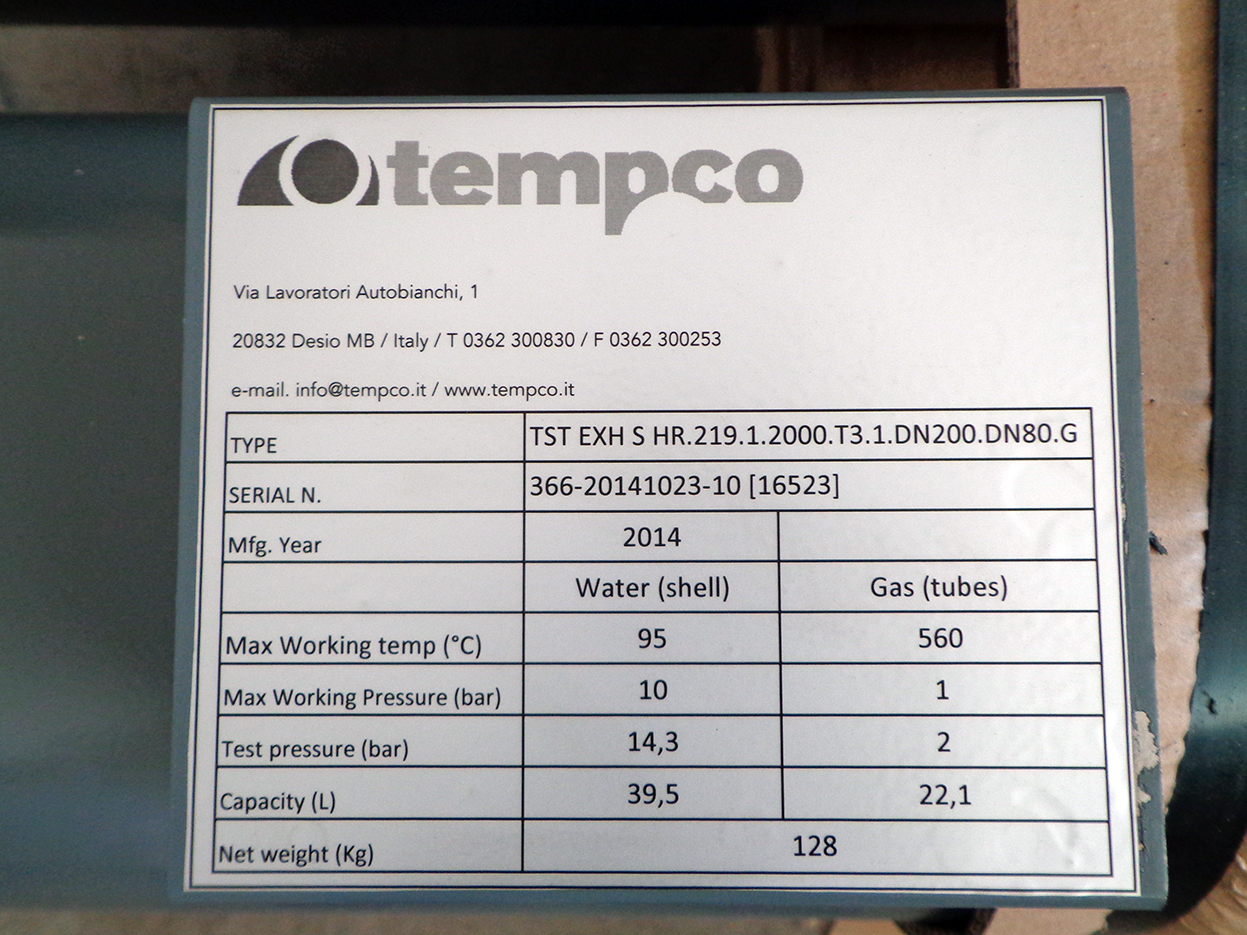

In this case, the Tempco exchangers work both on the jackets, with a brazed plate exchanger, and on heat recovery from exhaust fumes, with a shell and tube exchanger.

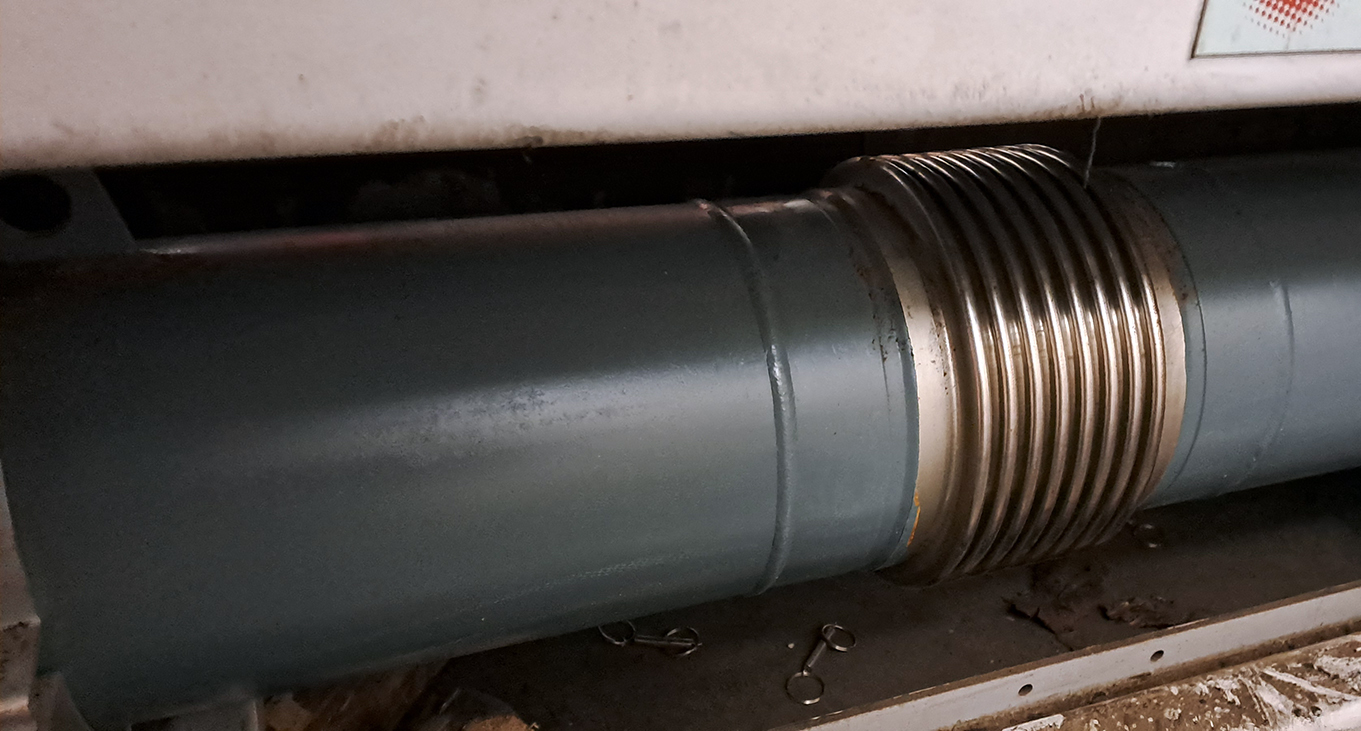

After 11 years of work, the customer then called us requiring a replacement of the gaskets on the flanges, which had worn out over time. At the time of installation, Tempco had supplied the exchangers, while the customer preferred to rely on another supplier for the gaskets, although to be fair, these are anyway components subject to wear and therefore requiring maintenance.

Overall, we can say that we are very satisfied with the successful application realized for this customer.