The technology of Tempco’s PCHE printed circuit exchangers is described in the new Hydrogen Guide 2024 of Hydrogen Fair, part of the EIOM circuit with mcTER and La Termotecnica, which offers many interesting insights into the evolution of the hydrogen sector in Italy.

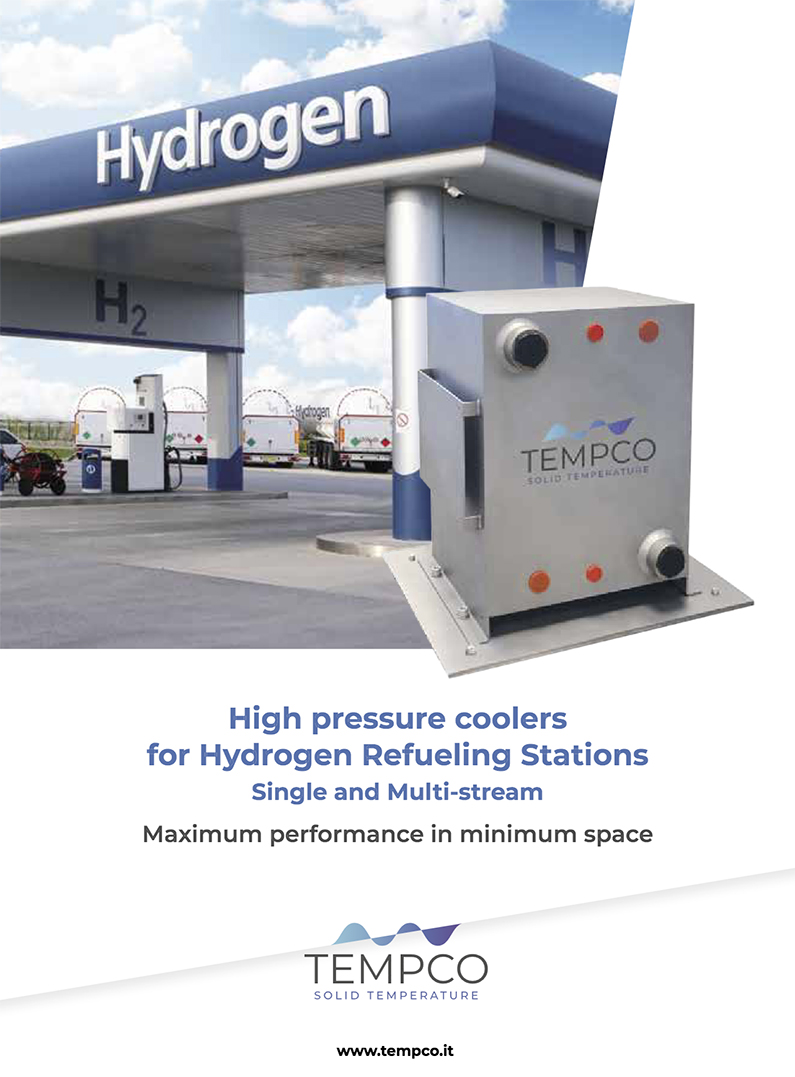

PCHE exchangers offer an ideal application for cooling gas at very high pressure and temperature in the compression cycles of hydrogen refueling stations. Thanks to the diffusion bonding construction technique and the microchannel structure of the plates, obtained with a special chemical photo-etching process, these exchangers guarantee very high heat transfer efficiency, resistance to extreme working conditions with high pressure and temperatures and the necessary operational safety in hydrogen refueling stations.

A key technology for creating an adequate refueling infrastructure capable of supporting the growth of the hydrogen industry and the diffusion of fuel cell vehicles for the sustainable mobility of tomorrow.

On the Tempco page on the Fiera Idrogeno website you will find a collection of articles and applications developed for the hydrogen industry.

Here is the complete article on Tempco PCHE exchangers in hydrogen refueling stations featured in the new Hydrogen Guide 2024. Enjoy the reading!