Let’s gonna talk again about PCHE, printed circuit heat exchangers. This week Tempco is participating at the Hydrogen Expo, in Piacenza, Italy (hosted by the MCD stand in Pav.1 Booth B118), an exhibition dedicated to the hydrogen technologies. Tempco will be present because this is a very interesting market with very interesting applications, and especially with regard to hydrogen distribution applications.

Everyone is involved in problems related to mobility and sustainability, and one of the incoming solutions for the near future is related to cars or anyway transports and vehicles using hydrogen as energy source in the powertrain. Hydrogen both as a direct source of energy for internal combustion engines or as indirect source of energy to power electric engines in electric vehicles and e-mobility solutions.

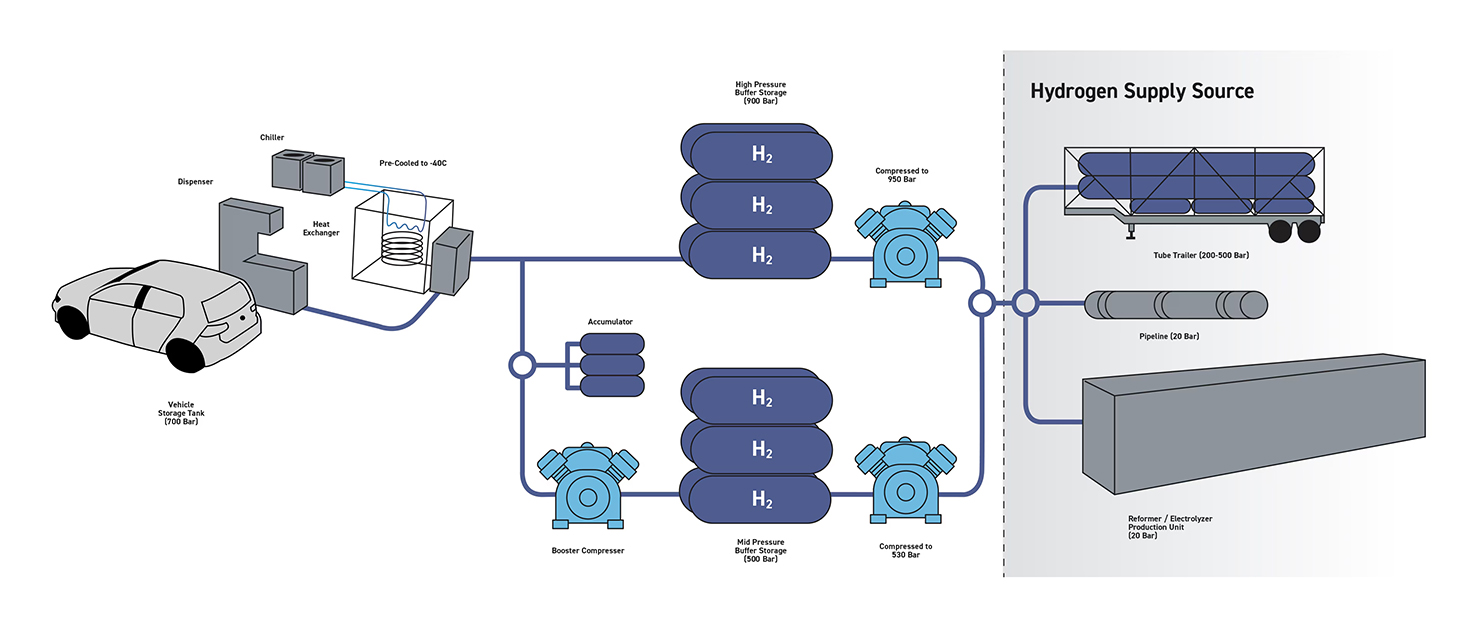

In fact, we are especially speaking about hydrogen distribution stations, for the refueling of cars and vehicles powered with hydrogen, thus employing hydrogen powered engines. In particular, these distribution systems require the presence of heat exchangers in order to decrease the hydrogen temperature during the refueling operations for these kind of vehicles, cars, buses, trucks or whatever. Decreasing the hydrogen temperature and storing a high pressure volume of it aiming at lowering refueling times and to be able to store the hydrogen at the proper pressure level.

PCHE exchangers, thanks to their peculiar characteristics, consisting in being fully manufactured in stainless steel, completely welded, and thus constructed in a compatible material, being full-inox, these exchangers are the ideal solution for hydrogen cooling tasks.

We have seen it already in other videos focused on PCHE exchangers employed in multi-stage compressors for hydrogen and technical gases. In this case a mono-stage exchanger is employed for the direct cooling of hydrogen but with very high operating pressures.

The application is very intriguing. If you’re interested, come visit us in Piacenza at Hydrogen Expo, Pav. 1 Booth B118, or contact us.